The HDPE shredder machine plays a crucial role in the waste management and recycling industry, particularly as the need for effective plastic recycling solutions continues to rise. High-Density Polyethylene (HDPE) is one of the most widely used plastics, and its proper disposal and recycling are essential for reducing environmental impact. With the advancement of technology, modern HDPE shredder machines are equipped with features that enhance efficiency and operational cost-effectiveness, making them a vital investment for businesses involved in waste processing.

In this comprehensive overview, we will delve into the top features of HDPE shredder machines expected in 2025. These machines are designed to optimize the shredding process, ensuring maximum throughput while minimizing energy consumption. Energy-efficient motors, advanced blade designs, and smart technology integration are just a few of the attributes that highlight the evolution of these machines. Furthermore, understanding the cost benefits associated with investing in state-of-the-art HDPE shredding equipment can provide businesses with insights into better managing their operational expenses and resources.

By examining the latest innovations and benefits of HDPE shredder machines, stakeholders in the recycling sector can make informed decisions that align with both economic goals and environmental sustainability. As we explore these advancements, it will become clear how the future of efficient plastic waste management lies in the capabilities of modern shredding technology.

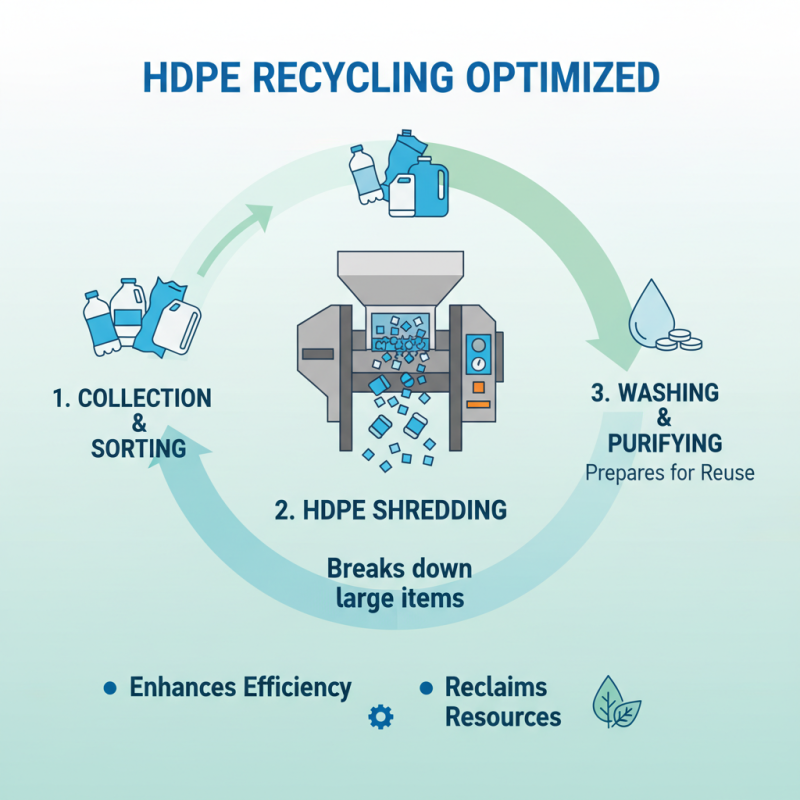

The HDPE shredder machine plays a pivotal role in the recycling industry, particularly when it comes to processing high-density polyethylene (HDPE) materials. These machines are designed to break down larger HDPE items—such as bottles, containers, and plastic scraps—into smaller, manageable pieces. This initial shredding not only facilitates the recycling process but also enhances the efficiency of subsequent operations like washing and purifying the material for reuse. By optimizing the size of the shredded material, companies can significantly improve their recycling efficiency, allowing them to reclaim valuable resources while minimizing waste.

When considering the installation of an HDPE shredder machine, it's essential to prioritize certain features that will enhance your operation. Look for machines equipped with robust cutting blades that offer longevity and consistent performance. Energy efficiency is also a crucial factor; machines designed with lower power consumption can yield significant cost benefits over time. Additionally, consider the machine's throughput capacity, as this will directly impact your production rates and overall profitability.

Tips: Always ensure that the HDPE shredder you choose fits your specific processing needs. Conducting a thorough assessment of your material input and desired output can help in selecting the right machine. Regular maintenance is vital for maintaining the efficiency and longevity of your shredder; consider implementing a routine check-up schedule to prevent costly downtimes.

The efficiency of HDPE shredder machines is greatly enhanced by several key features designed to optimize their performance. One of the most crucial aspects is the blade design, which is engineered for maximum cutting efficiency. Advanced blade configurations allow for smoother and quicker shredding of high-density polyethylene (HDPE), ensuring that the material is processed uniformly. This not only improves throughput but also minimizes energy consumption, contributing to more sustainable operations.

Another significant feature is the incorporation of automated control systems. These systems enable real-time monitoring of the shredding process, adjusting the machine's parameters based on the input material's characteristics. This adaptability ensures consistent performance, reduces the risk of jams, and allows for efficient operation even when handling various types of HDPE waste. Additionally, many machines are equipped with noise-reduction technologies, making them suitable for use in environments where sound levels are a concern.

Robust construction and user-friendly design also play critical roles in enhancing the efficiency of HDPE shredders. A sturdy build limits vibrations and increases durability, while simplified maintenance protocols ensure that downtime is minimized. Furthermore, machines with intuitive interfaces allow operators to easily manage settings and troubleshoot issues, leading to improved operational efficiency. Overall, these advancements not only bolster performance but also provide substantial cost benefits, making HDPE shredder machines a valuable asset in waste management and recycling processes.

Investing in advanced HDPE shredder technology presents significant cost benefits for businesses looking to enhance their material processing efficiency. According to a recent market analysis from Grand View Research, the global plastic recycling market is projected to reach $67.5 billion by 2028, indicating a growing demand for efficient recycling practices. By utilizing high-density polyethylene (HDPE) shredders, companies can optimize their recycling processes, ensuring that material is reduced to smaller, reusable sizes while minimizing energy costs. Advanced shredders are designed with efficiency-enhancing features, such as energy-efficient motors and automated feed systems, which significantly reduce operational downtime and maintenance costs.

Moreover, the initial investment in HDPE shredders can be counterbalanced by substantial long-term savings. Research from the Plastics Industry Association indicates that recycling plastic can save up to 88% of the energy required to produce new plastic from raw materials. This energy efficiency translates to lower utility bills and can even qualify businesses for renewable energy credits in some regions.

Additionally, businesses that adopt advanced shredders often experience reduced labor costs due to streamlined operations, allowing staff to focus on value-added activities rather than manual sorting or processing. By integrating these advanced technologies, companies not only fulfill regulatory compliance on waste management but also contribute positively to the bottom line, reinforcing the case for adopting innovative recycling practices.

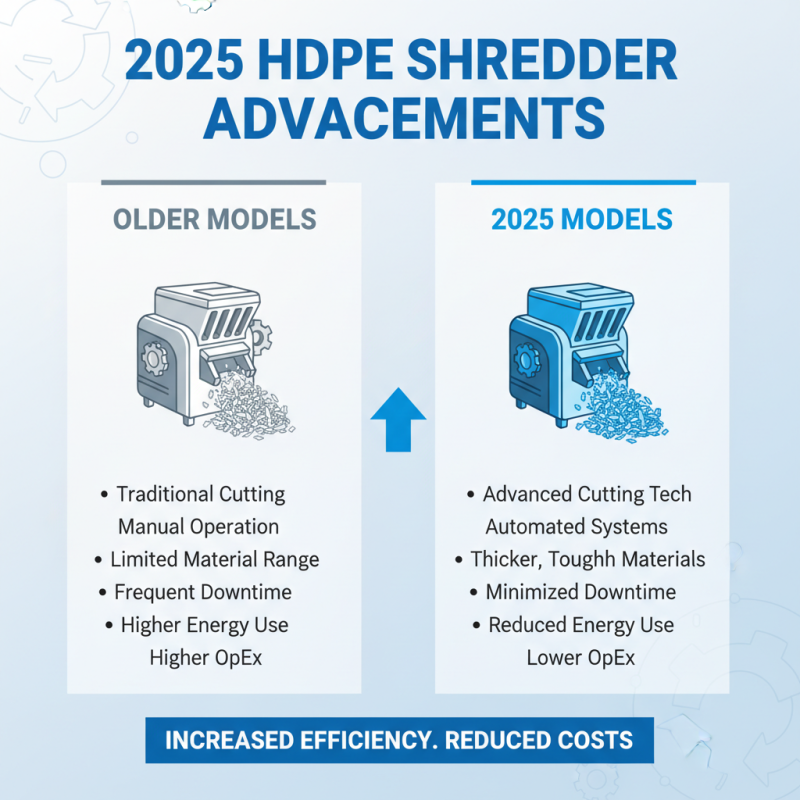

The 2025 HDPE shredder models have introduced significant advancements over their older counterparts, primarily in efficiency and operational costs. Modern shredders utilize advanced cutting technologies and automation, enabling them to process thicker and more challenging materials with ease. This innovation not only minimizes downtime during operation but also enhances the overall throughput, making them a more viable option for large-scale recycling facilities. Furthermore, improvements in blade design and motor efficiency lead to reduced energy consumption, translating to lower operational costs over time.

In contrast, older models often relied on less efficient motor systems and simpler blade configurations. These earlier designs required more frequent maintenance and were prone to operational hiccups, which could hinder productivity. While they may have been adequate for smaller tasks, they often fell short in meeting the demands of larger recycling operations. The shift towards 2025 HDPE shredders represents a pivotal step in embracing technology that not only boosts performance but also aligns with cost-saving measures, thereby making them a smart choice for businesses looking to enhance their recycling capabilities.

Maximizing efficiency in HDPE shredding processes is pivotal for manufacturers aiming to enhance productivity while minimizing operational costs. One of the core strategies is selecting the right shredder machine, which can significantly impact performance metrics. According to a recent industry report, efficient shredders can reduce energy consumption by up to 30%, translating to substantial cost savings over time. Additionally, implementing real-time monitoring systems allows operators to identify bottlenecks promptly, streamlining workflows and further increasing throughput.

When designing an HDPE shredding operation, it’s crucial to regularly maintain equipment to prevent downtime. Regular maintenance checks can extend the lifespan of machinery and ensure they operate at peak efficiency. Furthermore, optimizing the input material's size and moisture content can lead to better shredding results and lower energy use. A study suggests that reducing the input material's size before shredding can boost the final output quality and processing speed.

Tips: Train staff on best practices for operating shredders, including the importance of uniform feeding and monitoring of machine performance. Consider scheduling maintenance during off-peak hours to minimize disruption and ensure continuous operation. Adopting an automated feed system may also increase consistency and efficiency in the shredding process.