In the evolving landscape of recycling technology, the demand for effective Aluminium Alloy Shredders continues to rise. An industry expert, John Smith, asserts, "Choosing the right shredder can significantly enhance recycling efficiency." This statement highlights the critical role that the right machinery plays in processing aluminium alloys, a material known for its widespread use and recyclability.

Aluminium alloys are increasingly integrated into various products, from automotive to packaging. Therefore, finding the right Aluminium Alloy Shredder can drastically reduce waste and improve material recovery rates. However, not all shredders are created equal. The market is flooded with options, and making a precise choice can be daunting.

Potential users may struggle with identifying the best features to suit their operations. Each shredder may have distinct capacities, sizes, and innovations. Investing in the wrong equipment can lead to processing inefficiencies and increased costs. It is crucial to weigh options carefully and consider all factors before making a decision. The journey to finding the best Aluminium Alloy Shredder is not as straightforward as it seems.

When considering aluminium alloy shredders, features matter. A powerful motor is crucial. Look for options that offer at least 15-20 horsepower. This ensures robust handling of various materials. According to recent industry reports, shredders with higher horsepower significantly increase efficiency in processing.

Durability is another key aspect. The shredder's build should withstand heavy usage. Materials like hardened steel are preferable. They resist wear and tear, prolonging the machine’s life. Yet, some cheaper models use lighter materials that could fail quickly. These often lead to increased maintenance costs.

Additionally, user safety features should not be overlooked. The inclusion of emergency stops and safety guards is essential. Statistics indicate that proper safety measures reduce workplace injuries by 30%. Some machines lack comprehensive safety features, raising concerns. Regular checks and a solid maintenance routine can mitigate risks but aren't foolproof. Ultimately, the right blend of these features can create an effective and safe shredding environment.

When considering aluminium alloy shredders, it’s essential to analyze various brands and their features. The industry has seen a rapid increase in demand, with a reported growth rate of 5.2% annually through 2026. This demand can be attributed to the recyclability and durability of aluminium alloys. Shredders play a crucial role in the recycling ecosystem, making their effectiveness vital.

Efficiency varies significantly among brands. Some tools excel in processing speed, reaching up to 1,500 kg per hour. Other models may focus on energy consumption, boasting 30% less energy use than older models. However, many brands still struggle with maintenance concerns, leading to downtime. Users report that even reliable brands need regular parts replacement. This can add unexpected costs over the years.

Different features serve various user needs. For example, some shredders offer multiple cutting options. This versatility is appealing but may complicate usage. Simplicity often yields better results in the long run. Data shows that simpler models have higher satisfaction ratings. In the end, prospective buyers should weigh the pros and cons carefully. Each brand has strengths and weaknesses. Understanding these nuances can lead to better choices.

| Model | Shredding Capacity (kg/h) | Power (kW) | Weight (kg) | Noise Level (dB) | Price Range ($) |

|---|---|---|---|---|---|

| Model A | 300 | 15 | 200 | 85 | 5000 - 7000 |

| Model B | 500 | 25 | 350 | 92 | 10000 - 12000 |

| Model C | 400 | 20 | 300 | 88 | 7000 - 9000 |

| Model D | 350 | 18 | 250 | 90 | 6000 - 8000 |

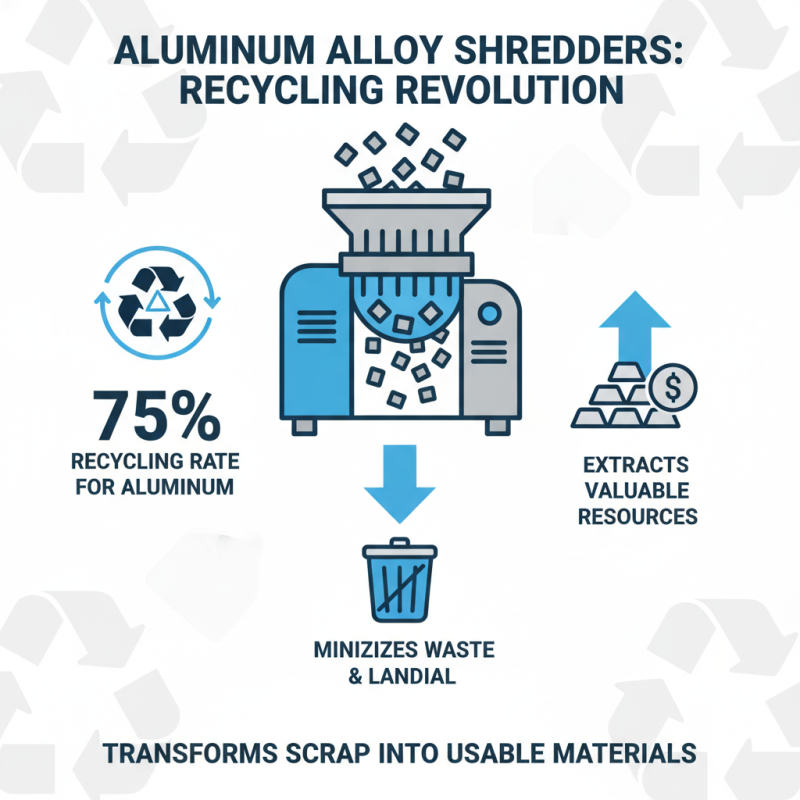

Aluminium alloy shredders are pivotal in recycling. They transform scrap metal into usable materials. With a recycling rate of 75% for aluminum, there is significant value in effective shredding processes. These machines help extract valuable resources, minimizing waste.

Using aluminium alloy shredders offers multiple benefits. They enhance the material’s purity by reducing contamination from other metals. According to industry reports, clean aluminum can fetch up to 90% of its original value. Shredding allows for easier transportation and storage. Smaller, lighter pieces reduce shipping costs and improve processing efficiency.

However, there are challenges. Operating these machines requires energy and maintenance. The initial investment may be high for smaller operations. Yet, many find that the long-term savings outweigh these costs. Optimizing the shredding process demands careful consideration of machine settings. Balancing speed with material integrity is essential for quality output.

Proper maintenance of an aluminium alloy shredder is crucial for peak performance. Regular checks can uncover issues before they escalate. According to a recent industry report, over 30% of shredders fail due to inadequate upkeep. This statistic underlines the need for a routine maintenance schedule.

Lubrication is essential. Experts recommend using high-quality grease for critical components. Ignoring this leads to wear and potential breakdowns. Additionally, sharpening blades contributes to efficiency. Dull blades increase power consumption by up to 20%. Periodic inspections of blade sharpness can help maintain optimal shredding quality.

Another aspect often overlooked is cleanliness. Residue can accumulate over time, impacting shredder function. Cleaning should occur weekly, especially after heavy use. Finally, training personnel on operating procedures reduces the risk of mishandling. Incorrect use can lead to costly repairs or injuries. Prioritizing these maintenance tips can enhance the longevity and performance of your aluminium alloy shredder.

The environmental impact of aluminium alloy shredding is noteworthy. Shredding helps recover valuable materials, reducing waste in landfills. However, the process does generate some emissions. Dust and particles can escape, affecting air quality. It’s crucial to implement effective filtration systems to minimize this issue.

Energy consumption is another concern. Shredding consumes power, contributing to carbon footprints. Yet, energy-efficient machines are emerging, striving to reduce this impact. Companies must weigh the benefits and drawbacks. The potential for recycling is significant, but the trade-offs warrant careful consideration.

Water usage is also relevant. Shredding machines often require water for cooling. If not managed properly, this can lead to wastage. Water recycling systems could improve efficiency. There’s room for growth and improvement in this area. Balancing ecological benefits and environmental costs is essential for sustainable practices.