In 2026, choosing the right Small Tire Shredder is crucial. This decision impacts both the environment and your operations. Many businesses overlook essential factors when selecting shredders.

The right shredder efficiently breaks down tires. Yet, some models can be inefficient. They may produce uneven sizes or leave excess materials. Understanding these nuances helps in making informed choices.

Additionally, consider maintenance needs. Some shredders may require more frequent repairs. This can increase long-term costs. A Small Tire Shredder should balance efficiency with durability. Reflection on these details can lead to better investment decisions.

The small tire shredder market is gaining momentum in 2026. An estimated growth rate of 5.7% is expected over the next few years. This trend is driven by increasing environmental concerns. The reduction of waste is a priority for many industries. Small tire shredders play a significant role in this process.

Recent reports indicate that around 1 billion tires are discarded annually worldwide. These tires can take up to 1,000 years to decompose. Such statistics clarify the need for efficient recycling solutions. Small tire shredders help convert waste tires into manageable sizes. This creates opportunities for reuse in various applications. However, not all shredders can meet the rising demand for efficiency and quality.

The market is witnessing innovations in design and technology. Some manufacturers are adopting advanced materials to enhance durability. Despite this, many shredders still face challenges. Issues like energy consumption and maintenance costs need careful consideration. A balanced approach is key for companies aiming to maximize productivity while minimizing environmental impact. As the market grows, the pressure to innovate will intensify.

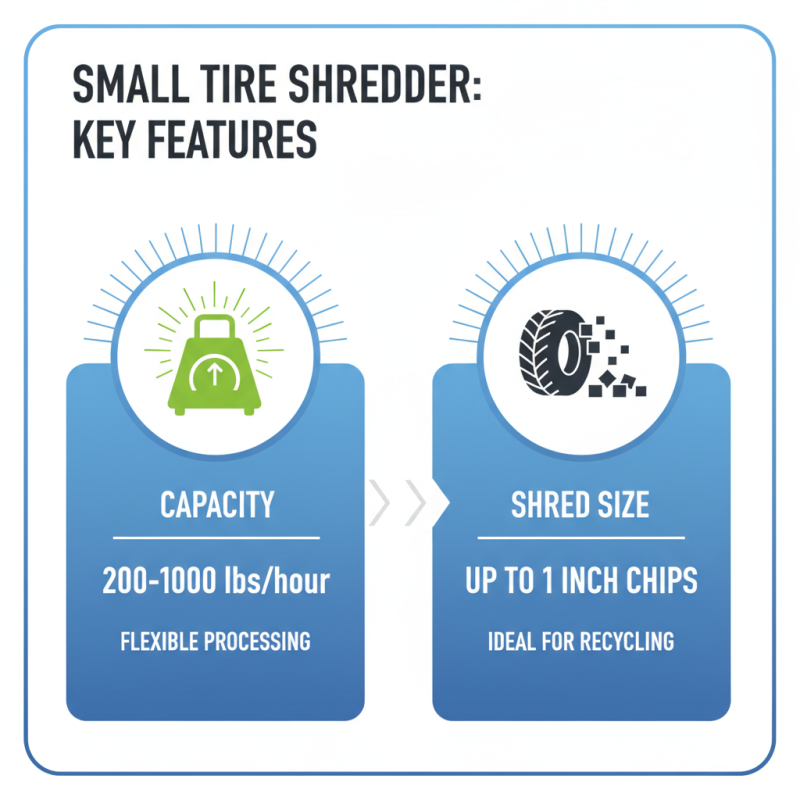

When choosing a small tire shredder, several key features stand out. First, consider the shredder's capacity. Machines that process between 200 to 1000 pounds per hour are popular in many settings. This range allows for flexibility depending on your needs. Additionally, the size of the shredded pieces matters. A machine that produces chips up to 1 inch can be ideal for further recycling processes.

Another crucial specification is the motor power. Most effective small tire shredders have motors ranging from 10 to 30 horsepower. This gives them the strength needed for efficient tire breakdown. A machine with a higher horsepower can handle thicker rubber more easily. Yet, energy consumption is a concern; a balance is essential. Reports show that excessive energy use can lead to higher operational costs.

Durability is also vital. Some shredders use high-quality steel blades, which contribute to longevity. However, maintenance is often overlooked. Regular checks and timely replacements can make a big difference. You want a shredder that performs well over time. Additionally, consider the noise level. Many shredders can run quite loudly, which may raise concerns in community settings. Balancing effectiveness and noise control can be challenging—something often overlooked in initial evaluations.

Tire shredding plays a significant role in recycling. It helps reduce waste in landfills. By converting tires into small pieces, we create valuable materials. These materials can be re-used in various industries. For example, shredded rubber can be utilized in asphalt for roads. This process enhances durability and reduces noise.

However, the environmental impact is not entirely positive. Tire shredding can produce harmful emissions. Dust and particles may enter the air during this process. Additionally, improper disposal of leftover materials poses risks. It is crucial to have proper recycling programs in place. They can minimize these adverse effects and maximize benefits.

Despite the potential advantages, challenges remain in the tire recycling process. There are limited facilities for effective recycling. Many tires still end up in landfills. Awareness is necessary to push for better solutions. Encouraging community initiatives can foster responsible disposal habits. Reducing the overall demand for new tires is also vital. Each step helps promote a cleaner environment.

When considering small tire shredders, it's crucial to evaluate cost-effectiveness. Different brands offer various features that can greatly impact your budget. A machine that handles the volume you need might save you money in the long run. Factors like operational efficiency and maintenance are also important. If a shredder requires frequent repairs, it may not be the best choice.

Some brands excel in energy efficiency, reducing long-term operational costs. Others may promise high throughput but can fall short when it comes to reliability. A machine that breaks down often can lead to costly downtime. It's essential to analyze both upfront costs and potential hidden expenses.

User reviews often highlight the importance of support and service. Sometimes, a cheaper machine lacks adequate customer support. This can result in frustration and higher costs for repairs. Cost-effectiveness isn’t solely about the sticker price; it encompasses overall performance and reliability. Balancing these aspects is key in identifying the best investment.

When it comes to tire shredding, safety standards and regulatory compliance are crucial. Industry regulations aim to protect workers and the environment. Many countries have set specific guidelines for handling and processing tires. The right equipment can meet these regulations effectively. Ensure your tire shredder complies with local laws. This reduces the risk of penalties or shutdowns.

It's vital to stay updated on safety practices. Workers should receive training on how to operate shredders safely. Proper PPE (Personal Protective Equipment) is necessary. This includes gloves, helmets, and ear protection. Regular maintenance of the shredder also prevents accidents. A well-maintained machine runs smoothly and is safer for operators.

Tips: Always have an emergency plan in place. Keep first aid kits accessible. Regular drills ensure everyone knows what to do in case of an emergency. Review safety measures frequently. Communication is key in busy environments. Ensure all staff can report potential hazards easily. Address any concerns promptly to promote safety in the workplace.