In the rapidly evolving landscape of waste management and recycling, Aluminium Alloy Shredders play a pivotal role in transforming discarded materials into valuable resources. According to a report by Smithers Pira, the global market for aluminum recycling is projected to reach $100 billion by 2026, with a significant portion driven by the increasing demand for lightweight and sustainable materials across various industries. However, despite this lucrative potential, Aluminium Alloy Shredders face several challenges, including the need for advanced technology to efficiently process complex alloy compositions and rising operational costs. Furthermore, a study by the International Aluminium Institute highlights that only 75% of aluminum ever produced is still in use, emphasizing the urgent need to enhance recycling processes to recover the remaining materials. Understanding these challenges is crucial for improving the efficiency and effectiveness of Aluminium Alloy Shredders in modern recycling practices.

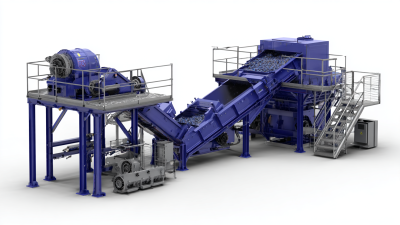

Efficient aluminium alloy shredding is crucial in modern recycling processes, as it directly impacts material recovery rates and overall sustainability. Aluminium alloys are widely used in various industries due to their lightweight and durable properties. However, these materials present unique challenges during recycling, primarily due to their complex compositions and the need for precise separation techniques. High-quality shredding facilitates the breakdown of these alloys, allowing for the effective separation of different metals and contaminants, which ultimately leads to improved recycling efficiency.

Additionally, the importance of modern shredding technology cannot be overlooked. Advanced shredders can optimize the size reduction of aluminium alloys, ensuring that the resulting materials are suitable for re-melting and repurposing. This not only enhances the economic viability of recycling operations but also encourages a circular economy where valuable resources are reclaimed and reused. As the demand for sustainable practices increases, investing in efficient aluminium alloy shredding solutions will play a pivotal role in addressing environmental concerns and promoting responsible waste management.

Aluminium alloy shredders face a myriad of technical challenges as the demand for efficient recycling solutions intensifies. One prominent issue is the complexity of processing different alloy compositions. Each aluminum alloy can exhibit unique properties, such as varying densities and strengths, which can complicate the shredding and separation processes. This necessitates advanced shredding machinery that can adjust settings based on the specific materials being processed, enhancing efficiency and reducing wear on equipment.

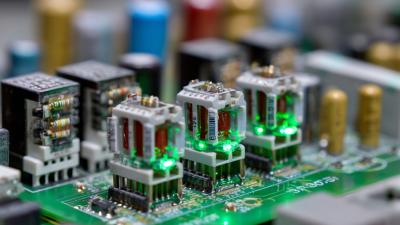

To tackle these challenges, innovations in technology can play a significant role. For instance, integrating advanced sensing technologies, such as Laser-Induced Breakdown Spectroscopy (LIBS), allows recyclers to identify alloy compositions in real time, optimizing the shredding parameters accordingly. Additionally, employing alternative methods, such as additive manufacturing techniques, can facilitate the production of specialized components that improve the performance and longevity of shredders. These solutions not only address current inefficiencies but also bolster the circular economy by ensuring that aluminum recycling is both sustainable and effective.

Maintaining aluminium shredding equipment is crucial for optimizing processing efficiency and maximizing the recycling of this valuable material. According to a report by the Aluminium Association, approximately 75% of aluminium produced in the last 140 years is still in use today, highlighting the importance of effective recycling practices. Regular maintenance not only extends the life of shredding machines but also enhances their performance, enabling the processing of up to 3 tons of aluminium waste per hour when properly maintained.

To ensure optimal performance, operators should implement a rigorous maintenance schedule that includes regular inspections, lubrication, and replacement of worn parts. Utilizing predictive maintenance techniques can also lead to significant cost savings; a study by the National Institute of Standards and Technology found that predictive maintenance can reduce unexpected shutdowns by up to 50%. Additionally, adhering to best practices such as keeping the shredding area clean and ensuring an efficient feed rate can prevent equipment malfunctions and enhance throughput, ultimately contributing to a more sustainable recycling process.

The recycling of aluminium alloys is becoming increasingly crucial in today's sustainable world. However, traditional shredding methods face significant challenges, such as material contamination and the need for high efficiency in processing. Innovative technologies are being developed to tackle these issues, aimed at enhancing the overall efficiency of aluminium alloy recycling. One promising approach is the implementation of advanced sensor systems and artificial intelligence. These technologies can accurately identify and sort different aluminium types, minimizing contamination and ensuring that the recycling process is more streamlined.

The recycling of aluminium alloys is becoming increasingly crucial in today's sustainable world. However, traditional shredding methods face significant challenges, such as material contamination and the need for high efficiency in processing. Innovative technologies are being developed to tackle these issues, aimed at enhancing the overall efficiency of aluminium alloy recycling. One promising approach is the implementation of advanced sensor systems and artificial intelligence. These technologies can accurately identify and sort different aluminium types, minimizing contamination and ensuring that the recycling process is more streamlined.

Moreover, new shredding techniques are being introduced, such as hydro-mechanical shredding. This method combines water and mechanical action to break down aluminium alloys more efficiently, resulting in less energy consumption and reduced wear on equipment. Additionally, developments in sorting technology, like electromagnetic and eddy current separators, are empowering recyclers to separate aluminium alloys from other materials more effectively. By adopting these innovative solutions, the aluminium recycling industry can significantly improve its efficiency, reduce operational costs, and contribute to a more sustainable future.

In the modern recycling landscape, aluminium alloy shredders face significant challenges shaped by a constantly evolving framework of regulations and standards. Compliance with stringent environmental regulations is paramount, as it directly affects operational efficiency and safety. For instance, according to a recent report by the Aluminium Association, industries must adhere to standards that limit pollutant emissions, which can impose additional financial and operational burdens on shredding facilities. Failing to comply can result in hefty fines and stricter oversight, highlighting the importance of staying informed about regulatory changes.

Tip: Regularly review compliance guidelines from local environmental authorities to ensure that your operations are always aligned with current standards.

Furthermore, the implementation of international standards such as ISO 14001 for environmental management systems can streamline operations and enhance sustainability. This standard not only aids in mitigating the environmental impact of shredding processes but also bolsters a company's reputation in the market. A study indicated that companies adopting these standards experienced a 20% reduction in waste generation, ultimately leading to more efficient resource use.

Tip: Engage with certification bodies to explore which standards can be integrated into your operations for improved compliance and efficiency.