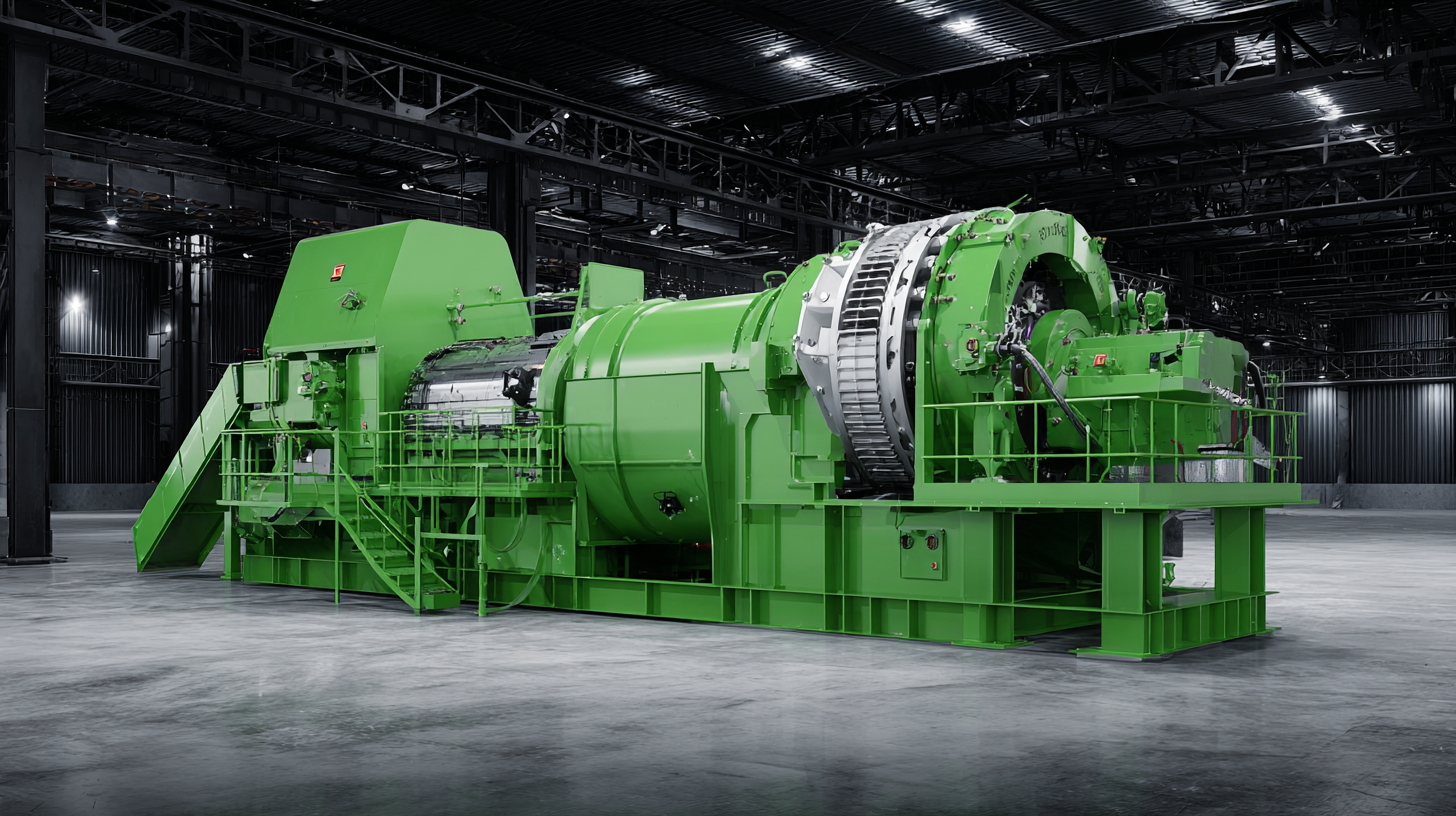

As the plastic recycling industry evolves, the demand for efficient and effective processing equipment such as the Plastic Head Shredder is becoming increasingly critical. Recent reports from industry leaders indicate that the global plastic waste management market is projected to reach $37.6 billion by 2025, highlighting an urgent need for advanced shredding technologies that can handle varied plastic types while ensuring optimal operational efficiency.

As the plastic recycling industry evolves, the demand for efficient and effective processing equipment such as the Plastic Head Shredder is becoming increasingly critical. Recent reports from industry leaders indicate that the global plastic waste management market is projected to reach $37.6 billion by 2025, highlighting an urgent need for advanced shredding technologies that can handle varied plastic types while ensuring optimal operational efficiency.

However, the best Plastic Head Shredder faces several challenges, including the need for innovative design to accommodate diverse feed materials, compliance with stringent environmental regulations, and the integration of automation technologies. Insights from industry data reveal that overcoming these obstacles is essential for manufacturers aiming to remain competitive in a rapidly changing market landscape.

As we delve deeper into the 2025 technical trends and best practices, it becomes clear that addressing these challenges is pivotal for harnessing the full potential of plastic shredding solutions.

When it comes to manufacturing plastic head shredders, one of the most pressing challenges is selecting the right materials. The balance between durability and cost can significantly impact both the performance of the machine and the overall profitability of production. Manufacturers need to consider not only the strength and longevity of the materials used but also how they align with budget constraints. For instance, using high-quality steel or reinforced composites can enhance the shredder's lifespan, but these materials often come at a premium price, leading to a complex decision-making process.

Moreover, the industry is seeing an increased demand for shredders that can handle a variety of plastic types, further complicating material selection. Different plastics have varying properties that could affect the shredding process, making it essential for manufacturers to use versatile materials that can withstand diverse workloads. This requires a deep understanding of material science and continual research into new compounds that offer better performance at lower costs.

In navigating these challenges, companies that stay ahead of the trends in material innovation will likely lead the way in producing more efficient and cost-effective shredders for the plastic recycling market.

The future of plastic head shredders is poised to be significantly shaped by technological innovations by 2025. As industries demand more efficient and sustainable solutions, advancements in shredding technology are becoming paramount. Innovations such as AI-driven sorting mechanisms and IoT integration are set to enhance operational efficiency, allowing shredders to optimize processing times and material recovery rates. This evolution not only reduces operational costs but also aligns with increasing environmental regulations aimed at minimizing plastic waste.

**Tips:** To stay ahead in the industry, keep an eye on developments in automation and machine learning that can enhance the functionality of your shredding equipment. Regularly update your machinery to incorporate the latest features that boost efficiency, such as smart sensors for real-time performance monitoring. Additionally, consider investing in employee training programs focused on these new technologies, ensuring that your team is well-equipped to maximize the benefits of modern shredding solutions.

Moreover, the integration of sustainable materials and energy-efficient designs will play a critical role in the future landscape of plastic shredders. Companies are increasingly turning towards eco-friendly designs that not only enhance performance but also reduce their carbon footprint. This shift represents an important trend in the industry, whereby manufacturers must adapt to remain competitive in a rapidly changing environment.

**Tips:** Evaluate the environmental impact of your shredding operations and implement practices that promote sustainability, such as energy-efficient machines and proper waste management strategies. It’s also beneficial to collaborate with suppliers who prioritize innovation in eco-friendly designs, positioning your business as a leader in sustainability within the plastic processing sector.

| Dimension | Current Challenges | Technological Innovations | Future Trends (2025) |

|---|---|---|---|

| Material Durability | Inefficient shredding of tougher plastics | Advanced blade materials | High-efficiency shredders |

| Energy Consumption | High operational costs | Energy-efficient motors | Sustainable energy sources |

| Maintenance | Frequent downtime for repairs | Predictive maintenance technology | Fully automated monitoring systems |

| Output Quality | Inconsistent particle size | Smart shredding algorithms | Uniform particle generation |

| Regulatory Compliance | Adapting to new environmental laws | Eco-friendly design practices | Enhanced recycling capabilities |

The adoption of head shredders in various industries faces a myriad of market dynamics, evidenced by current trends and data. As the 3D audio market is poised to reach $12.97 billion by 2026, with a compound annual growth rate (CAGR) of 16.9%, the demand for innovative audio solutions is on the rise. This growth can drive the enhancement of plastic head shredder technologies, as manufacturers seek to integrate these devices into more advanced audio production environments. However, the rental market for office spaces in China has seen its largest rental adjustment in three years, indicating potential barriers in capital allocation for capital-intensive equipment like head shredders.

Tips: Companies considering head shredders should analyze local market conditions closely. By leveraging forecasts such as IDC's prediction, which states that by 2029, the CAD market in China will grow to ¥14.68 billion—a 27% share—business leaders can intelligently identify investment opportunities that align with regional growth patterns. Additionally, keeping abreast of macroeconomic indicators, like China's GDP growth estimate of 5.0% for 2024, can guide firms in making informed decisions that mitigate risks associated with market volatility.

As the plastic shredding industry evolves, sustainability trends have emerged as a driving force behind operational strategies. Regulatory pressures are mounting as governments worldwide recognize the urgent need to address environmental concerns associated with plastic waste. Industries involved in plastic shredding must navigate these complex regulations, which often dictate the recycling processes, waste management protocols, and emissions controls required during shredding operations. Meeting these regulations not only protects the environment but also positions companies as responsible leaders in their field, enhancing their brand reputation.

In response to these challenges, many companies are adopting innovative technologies aimed at minimizing their ecological footprint. This includes investing in energy-efficient machinery, implementing closed-loop recycling processes, and exploring biocompatible materials. By prioritizing sustainability, these organizations not only comply with regulations but also cater to a growing consumer demand for environmentally friendly practices. The integration of sustainable practices within the shredding process not only mitigates regulatory risks but also opens up new market opportunities, allowing companies to thrive in an increasingly eco-conscious world.

In the rapidly evolving plastic head shredder sector, the competitive landscape is shaped by several key players that dominate market share and influence industry trends. Leading companies are investing heavily in innovation and technology to enhance shredder efficiency, reduce operational costs, and address environmental concerns. These advancements not only improve performance but also cater to the growing demand for sustainable waste management solutions.

As market dynamics shift, smaller firms are carving out niches by specializing in specific applications or offering customized solutions. This creates a diverse environment where traditional giants face competition from agile startups that leverage emerging technologies. The significance of staying attuned to market trends, such as automation and the integration of smart technology, cannot be overstated; companies must continuously adapt or risk losing their foothold in this increasingly competitive arena. Aspiring entrants need to navigate this landscape carefully, analyzing competitors and identifying gaps in service to effectively position themselves for success.