The growing importance of sustainability in today's world cannot be understated. Many industries are responding to environmental challenges by adopting innovative solutions. A key component in this shift is the use of a PLA shredder, which effectively handles polylactic acid materials. According to a recent report by the Ellen MacArthur Foundation, the global demand for bioplastics, including PLA, is expected to reach 6 million tons annually by 2024.

The adoption of a PLA shredder can significantly enhance recycling processes. This machine allows for efficient size reduction of PLA products, making them easier to process. Data shows that proper shredding can increase recycling rates by up to 50%. However, not all facilities utilize this technology yet. There’s still a gap in awareness regarding the benefits of a PLA shredder. The impact could be substantial, given that millions of tons of PLA waste are generated each year.

Choosing a PLA shredder is not just a matter of efficiency. It represents a commitment to sustainable practices. As more companies recognize the challenges of waste management, the importance of proper shredding becomes clearer. Efforts must continue to educate stakeholders about the potential of this technology in achieving a circular economy.

Recycling is essential in our world. Using a PLA shredder can greatly enhance your recycling efforts. PLA, or polylactic acid, is a biodegradable plastic. Shredding PLA makes it easier to process. It reduces the size of waste, allowing for more efficient recycling.

One benefit of using a PLA shredder is improved material handling. Shredded PLA takes up less space. This makes storage and transportation simpler. It can also speed up the recycling process significantly. When material is smaller, machines handle it better. However, not all shreds are created equal. Finding the right size is crucial. If shreds are too fine, it can complicate the recycling process.

Tips for effective shredding: Always check the shredder settings. Adjust them based on the material type. Make sure the shredder is clean and free of debris. Regular maintenance helps prevent jamming. This can be a hassle and can slow down your operation. Remember, efficiency is key in recycling. If shredding gets bogged down, the entire process suffers. Aim for consistency in shred size for better sorting post-shredding.

PLA, or polylactic acid, is a biodegradable plastic made from renewable resources. This material is derived from cornstarch or sugarcane. As such, it poses less of a threat to the environment compared to traditional plastics. In landfills, PLA can decompose within a few months, unlike conventional plastics which take centuries. However, the impact of PLA isn't entirely positive. The industrial composting infrastructure is essential for proper decomposition, but it's often lacking in many areas.

Using a PLA shredder can enhance recycling efforts significantly. Shredding PLA products makes it easier to process them. It allows for better mixing with other organic materials in composting facilities. Yet, practicality poses a challenge. Many people are unfamiliar with PLA's unique properties. Educating consumers on how to dispose of PLA correctly is crucial. Misinformation can lead to contamination in recycling streams. When mixed with non-biodegradable plastics, PLA loses its ecological advantages.

Choosing a PLA shredder contributes to reducing waste but requires reflection on broader recycling practices. Simply having the equipment isn’t enough. Community awareness is necessary for effective waste management. Encouraging local recycling initiatives can create a positive ripple effect. Ultimately, embracing PLA for recycling needs means being informed and proactive about its limitations and benefits.

When it comes to recycling, efficiency is key. A PLA shredder plays a significant role in enhancing waste management. PLA, or polylactic acid, is a biodegradable plastic derived from renewable resources. Shredding this material reduces its size, making processing easier and faster. Smaller pieces can be sorted and composted more efficiently.

Using a PLA shredder can save valuable time in recycling operations. It allows for quicker sorting and processing of waste. Moreover, it helps maintain cleaner operations. Shredders can also help avoid contamination, which is vital in recycling. Mix-ups can lead to higher disposal costs.

Tips for using a PLA shredder include maintaining sharp blades for optimal performance. Dull blades can slow down the process and create larger shreds. Regular maintenance is essential. Understanding the volume of PLA waste you handle is also important. Overloading the shredder can lead to mechanical issues. Always aim for a balance between efficiency and caution.

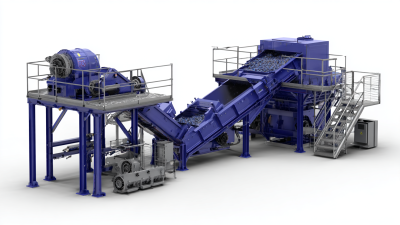

When it comes to recycling, choosing the right shredder can make a significant difference. A comparative analysis shows that PLA shredders, designed specifically for bioplastics, outperform traditional shredders in many aspects. PLA shredders maintain integrity while cutting through materials like polylactic acid.

Traditional shredders often struggle with these types of plastics, leading to more waste and inefficient processing.

Data from recent industry reports indicates that using PLA shredders can reduce operational costs by up to 30%. In contrast, traditional models often require more frequent repairs and maintenance. The efficiency of PLA shredders leads to higher throughput, meaning more materials processed in less time. This is crucial for businesses focusing on sustainability and eco-friendly practices.

Tip: Always assess the types of materials you'll be shredding. Not all shredders are created equal, and misusing them can lead to breakdowns. Consider the long-term benefits of investing in specialized equipment. Additionally, ensure proper training for staff on using and maintaining shredders effectively.

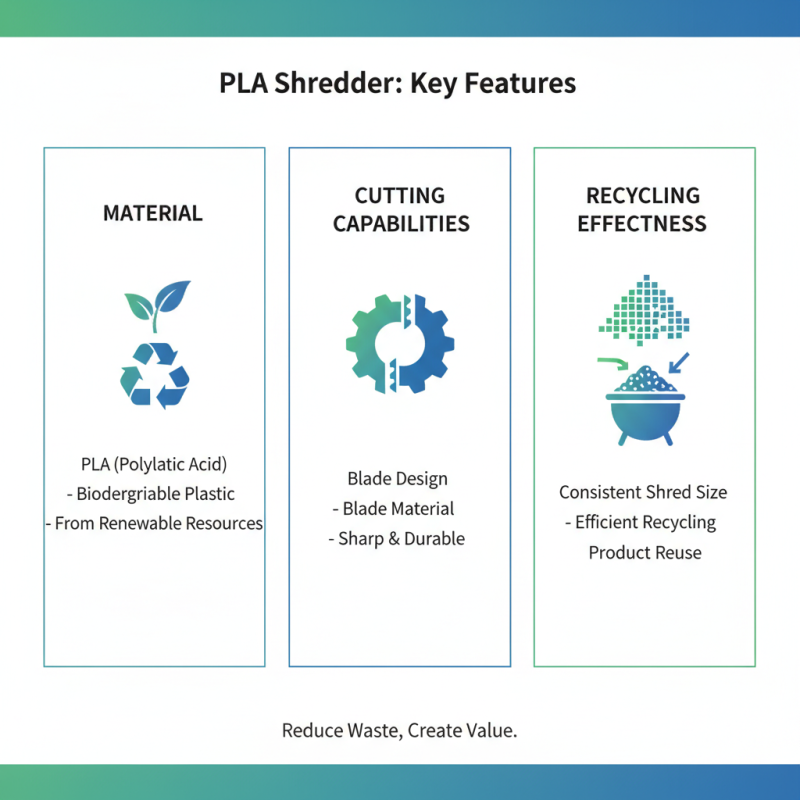

When selecting a PLA shredder, understanding key features is essential. PLA, or polylactic acid, is a biodegradable plastic derived from renewable resources. The effectiveness of a shredder greatly depends on its cutting capabilities. This includes blade design and material. Sharp, durable blades ensure a consistent shred size, which is crucial for effective recycling.

Consider the shredder’s capacity. A higher throughput means more material processed in less time. Some reports indicate that efficient shredders can handle up to 350 kg of PLA per hour. If you're working with large volumes, this feature can save time and labor costs. Noise levels are another important factor. Quiet models reduce workplace disruption and encourage a better working environment.

Tips: Look for energy-efficient shredders. They minimize environmental impact, aligning with recycling goals. Also, consider the machine's safety features. Automatic shut-off systems can prevent accidents. Reflect on how maintenance needs might affect your operation. Regular upkeep is vital for longevity. A shredder that’s hard to maintain may lead to downtime and increased costs.