Selecting the right Plastic Crusher Machine is crucial for businesses in waste management and recycling. According to the Global Plastic Recycling Market Report, the plastic recycling industry is projected to reach $50 billion by 2025. This growth highlights the importance of efficient machinery. Experts suggest that choosing the right machine can significantly impact productivity and cost-efficiency.

Dr. Emily Chen, a renowned expert in plastic processing technology, states, "Investing in the right Plastic Crusher Machine can determine the success of recycling operations." This sentiment resonates with many in the industry. It’s essential to consider factors like machine size, power consumption, and output capacity.

While many companies prioritize cost, overlooking quality can be detrimental. A poorly chosen Plastic Crusher Machine might lead to increased downtime and high maintenance costs. Every detail matters; therefore, careful consideration of specific needs is vital. Finding the perfect machine involves balancing efficiency and budget.

Choosing the right plastic crusher machine can be daunting. Various types are available to meet diverse needs. Understanding these machines is crucial.

One common type is the granulator. It breaks down large plastic items into smaller pieces. This type works well for manufacturing waste. Another option is the shredder. Shredders handle tougher materials but may produce larger particles. They are ideal for thick plastics.

Tips: Consider the size of your input materials. Larger items may require a more powerful machine. Pay attention to the output size as well. You want consistent pieces for recycling.

Don’t forget about maintenance. Some machines require regular checks to keep them running efficiently. Neglecting this can lead to unexpected breakdowns. Reflect on your operational needs. Investing in the right type of crusher can save time and costs long-term.

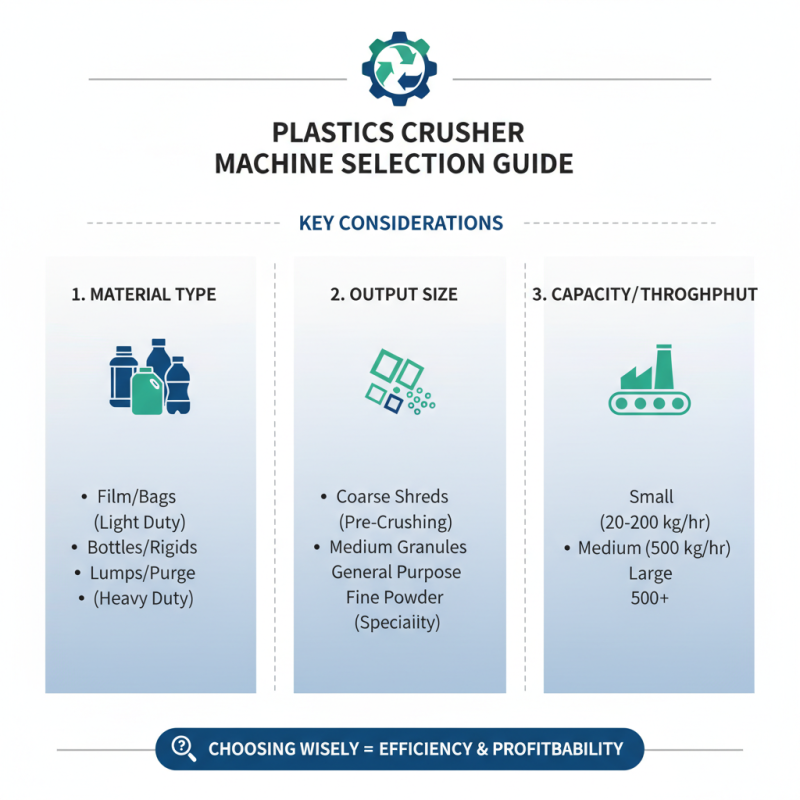

When selecting a plastic crusher machine, understanding your material types is crucial. Different plastics exhibit various characteristics, impacting how they break down. For instance, flexible plastics often require a different approach compared to rigid ones. This distinction can affect the efficiency of recycling operations and the quality of the recycled material.

Tips: Consider conducting a simple test with your materials. Observe how they react when exposed to crushing. This practical approach can reveal critical insights about your specific needs.

Evaluating your recycling requirements also plays a significant role. Are you focusing on volume or the type of recycled product? If it's about high volume, you might need more powerful machinery. However, achieving finer particle sizes might require machines with specific features. A mismatch here can lead to inefficiencies.

Tips: Always consult with experts. They can offer tailored advice based on your material characteristics and recycling goals. Sometimes, taking a step back to reassess your choices is beneficial. It leads to smarter decisions in the long term.

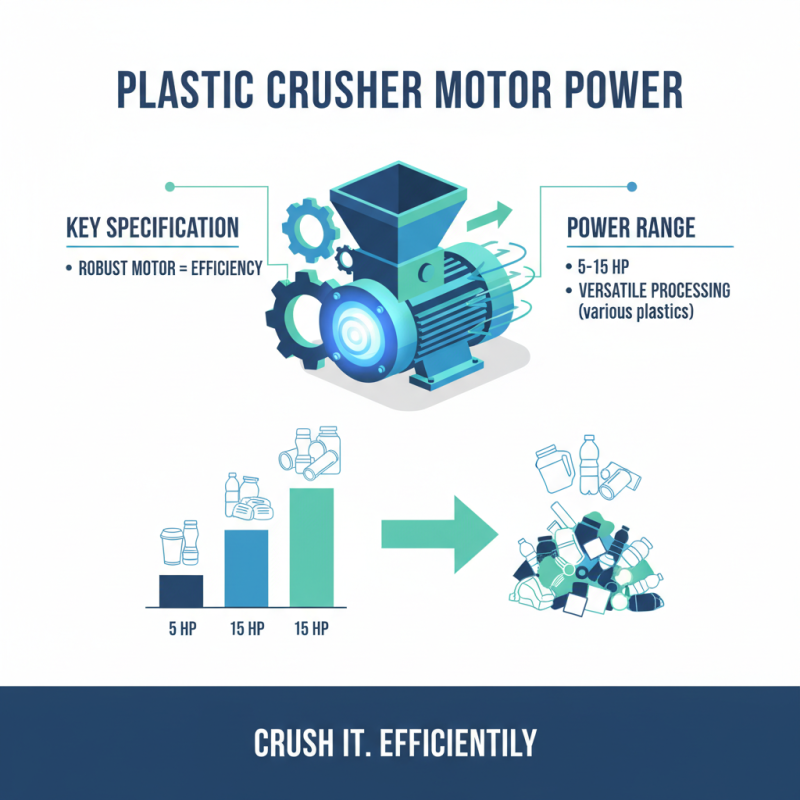

Choosing the right plastic crusher machine hinges on several key technical specifications. Among them, motor power is critical. A robust motor can easily handle different plastic types while maintaining efficiency. For instance, machines with a motor power ranging from 5 to 15 HP are suitable for a variety of operations, depending on the materials processed.

Another vital factor is the crushing chamber design. A well-crafted chamber ensures better feed processing. Ideally, this chamber should accommodate larger input materials and allow for a consistent output size. Some data indicate that a machine with a 300 mm feed size can increase processing speed by up to 30%.

Tips: Always check for adjustable settings. Flexibility in adjusting particle size can enhance operational versatility. Additionally, consider a machine with noise reduction features. This can significantly improve the working environment. A cheaper model might save costs initially but can lead to higher operational expenses in the long run.

Don't overlook the importance of safety features. Machines should have automatic shut-off functions. This is not just a precaution but an essential aspect of operational safety. Implementing machines without these features might seem acceptable at first but can lead to serious mishaps.

When selecting a plastic crusher machine, cost-effectiveness and lifespan are vital. A high-quality machine may have a higher upfront cost, but it can offer savings in the long run through durability. Cheaper models often break down easily, leading to frequent repairs or replacements. These costs can add up, impacting your budget significantly.

Evaluate the materials and components of the crusher. Machines made from durable metal typically last longer than those made from lower-grade materials. Checking reviews or getting advice on lifespan can help, yet sometimes the data is unclear. The market can be inconsistent, making it hard to judge quality based on price alone.

Don't overlook maintenance costs. Some machines require regular servicing, which can become an unforeseen expense. In addition, consider the energy efficiency of the model. A machine that consumes less energy can lower operational costs, yet finding efficiencies can sometimes feel overwhelming. Ensure the crusher aligns with your production needs and expected longevity. Balancing initial investment with long-term benefits is key in this decision.

When evaluating a plastic crusher machine, manufacturer reputation plays a crucial role. A reputable manufacturer often indicates reliable performance. Look for companies with a successful history in the industry. Research customer reviews to see real-world experiences. Not all manufacturers live up to their claims. A good reputation is built over time; it matters.

After-sales support is equally important. How quickly can you reach customer service? Will they assist with troubleshooting? Responding swiftly to technical issues is critical. Some companies promise support but fall short. Ensure they offer comprehensive service options. A lack of support can lead to prolonged downtimes.

Tips: Check online forums for user feedback. Visit facilities if possible. Ask other businesses about their experiences. Engage with their support team before purchase. Effective after-sales support can save time and money in the long run. Having the right support can make a significant difference in machine performance and longevity.