When it comes to recycling, choosing the right equipment is crucial. A Small Tire Shredder offers unique advantages that can greatly benefit your recycling operations. Traditional shredders are often bulky and expensive. In contrast, a small tire shredder is compact and more affordable. This makes it accessible for various recycling businesses.

Moreover, small tire shredders are versatile. They can handle different types of tires efficiently. Whether you process car, truck, or motorcycle tires, they adapt well. Their footprint is smaller, allowing for easier integration into any workspace. However, this does not mean they lack power. They effectively reduce tires to manageable sizes for further processing.

Additionally, a small tire shredder comes with operational benefits. Its energy consumption is lower, leading to reduced costs. Still, one must consider maintenance. Regular upkeep can ensure optimal performance. Reflect on your recycling needs and evaluate if a small tire shredder meets them. The efficiency and convenience it offers can be a game-changer in the recycling landscape.

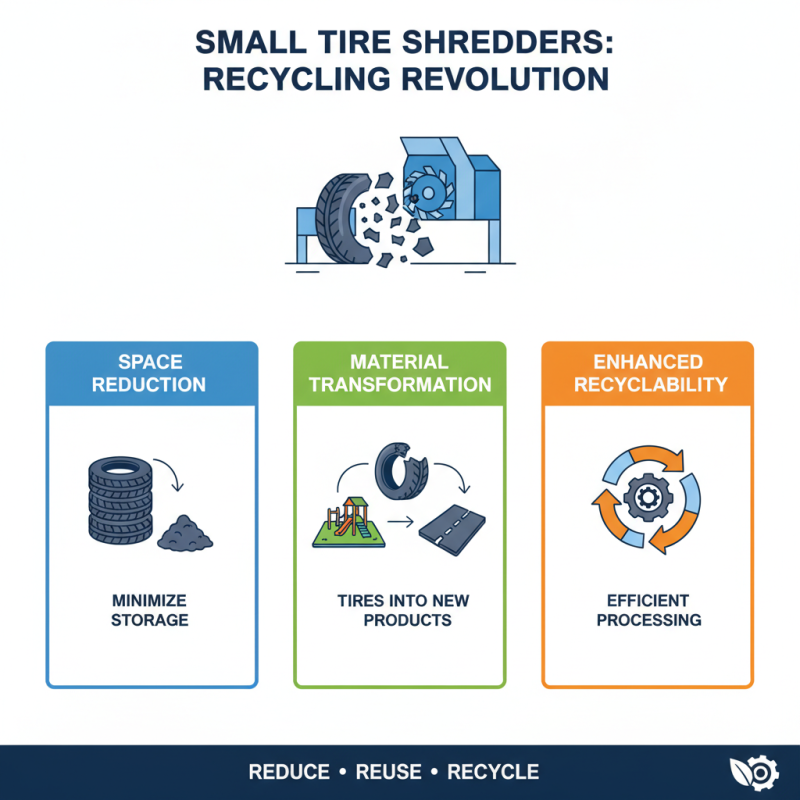

Small tire shredders play a vital role in recycling operations. They efficiently break down tires into smaller, manageable pieces. This process helps reduce space and enhances the recycling capability of the material. By using small tire shredders, businesses can minimize waste and convert tires into usable products.

One benefit of small tire shredders is their versatility. They can handle various rubber types, making them suitable for diverse recycling needs. These machines can produce different sizes of rubber granules, which are valuable in many applications, such as playground surfaces and rubberized asphalt. Additionally, compact machines save space in facilities, allowing for better organization.

**Tip:** Regular maintenance is crucial. Keep blades sharp for optimal performance. Don't ignore unusual sounds during operation. They might signal potential issues.

Another advantage is energy efficiency. Compared to larger shredders, small tire shredders often consume less power. This can lead to cost savings over time. However, operators must also consider the capacity. Not every small shredder will meet high-volume demands. Evaluating your specific needs is essential to avoid bottlenecks in the recycling process.

**Tip:** Monitor your production flow. Observe if the machine struggles with the workload. It’s important to adjust or upgrade when necessary.

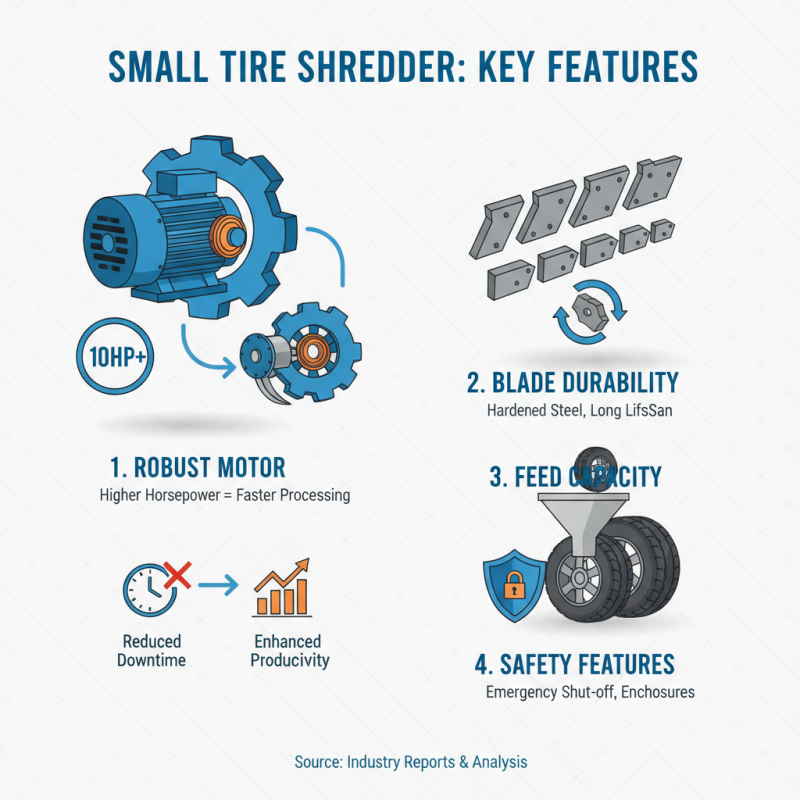

When selecting a small tire shredder, various key features deserve attention. A robust motor is essential. It affects the shredder's efficiency. Reports indicate that shredders with higher horsepower can process tires more swiftly. This can significantly reduce downtime, enhancing productivity for recycling operations.

Another critical feature is blade design. Sharp, durable blades ensure consistent shredding quality. They can handle different sizes and types of tires. Some shredders offer adjustable blade settings, accommodating various loads. This capability is vital for small businesses often dealing with diverse tire batches.

Lastly, consider the shredder's ease of maintenance. A simple maintenance routine saves time and costs. User-friendly designs simplify cleaning and part replacement. Data shows that facilities investing in accessible maintenance features reduce operational disruptions by 30%. Assessing these attributes helps ensure the chosen shredder meets your recycling needs effectively.

When considering tire shredders for recycling, small options present unique advantages. Compact and efficient, small tire shredders can easily fit in limited spaces. They typically consume less energy, making them cost-effective. Ideal for small to medium-sized operations, they handle tire recycling without overwhelming the facility. Managing smaller batches can be simpler, allowing for better control of the process.

On the other hand, large tire shredders boast higher capacity. They process more tires at once, saving time. However, they require significant upfront investment and require larger operational spaces. Maintenance can become complicated and costly with more extensive machinery. There’s also the challenge of ensuring compliance with safety regulations for larger units.

Ultimately, selecting between a small and a large tire shredder depends greatly on specific operational needs. It’s important to reflect on the long-term goals of recycling efforts. Will a small shredder suffice, or will growth demand larger capacity? Balancing efficiency with space constraints is crucial, but solutions are not always simple. Each option has its merits and drawbacks, inviting deeper consideration.

Small tire shredders play a crucial role in the recycling ecosystem. These machines help reduce used tires, turning them into manageable pieces. By doing so, they facilitate the recycling process, which is vital for our environment. According to a report by the Rubber Manufacturers Association, approximately 300 million tires end up in landfills each year in the U.S. alone. This overwhelming number contributes significantly to soil and water pollution.

The environmental impact of efficiently processing tires is profound. For every ton of tires recycled, up to 2,000 pounds of CO2 emissions can be avoided. Additionally, shredded tires can be repurposed into various products, like asphalt and playground surfaces. A study indicated that using tire-derived aggregates in construction could save 10-15% of conventional materials. This not only conserves resources but helps in reducing the carbon footprint.

However, not all small tire shredders are equal in efficacy. Some may struggle with processing efficiency, leading to inconsistent output sizes. This inconsistency can hinder the recycling process, making it imperative to choose the right shredder. The industry still faces challenges in maximizing output and minimizing waste generation during tire processing. Insights from the International Recycling Group suggest that ongoing advancements are needed to enhance machinery performance and further reduce the environmental footprint.

When considering recycling options, small tire shredders stand out for their cost-effectiveness. According to industry reports, businesses can save up to 30% on waste disposal fees. This is particularly beneficial for companies handling large volumes of scrap tires. The initial investment in a small tire shredder often pays off quickly as companies convert waste into reusable materials.

Operating a small tire shredder also reduces transportation costs. Businesses no longer need to transport whole tires to landfills. Instead, shredded tires occupy less space and can be moved more efficiently. A study showed that shredded tires are easier to manage in recycling processes. This not only helps in saving money but also supports a greener approach to waste.

However, not every business can fully capitalize on these advantages. Some may underestimate the energy costs associated with shredding. Others might struggle with maintenance and operational challenges. This highlights the importance of doing thorough research before making a decision. Investing in a small tire shredder can be beneficial, but businesses must weigh costs against actual savings.