Selecting the right Aluminium Alloy Shredder is crucial for efficiency and effectiveness. With various options in the market, making a choice can be overwhelming. Different models cater to distinct needs, from small workshops to large-scale recycling operations.

Consider your specific requirements before deciding. Think about the volume of materials you will process and the desired output quality. Some machines are efficient but can struggle with certain alloys, leading to unexpected downtime. Maintenance and operating costs are also important factors to consider. A more expensive model may save you money in the long run if it offers greater durability and performance.

Reflect on what features matter most to you. Look for shredders with adjustable settings or unique blade designs. It’s easy to overlook these details. However, they can significantly impact your shredding experience. With careful consideration, you can find an Aluminium Alloy Shredder that meets your needs.

When selecting an aluminium alloy shredder, it's crucial to understand the types of aluminium alloys. Aluminium alloys are categorized mainly into two groups: wrought and cast. Wrought alloys are manipulated mechanically. They are often used in products like sheets, plates, and extrusions. Cast alloys, on the other hand, are melted and poured into molds. These are common in components like engine blocks and complex shapes.

Wrought aluminium alloys, such as the 6000 series, offer excellent corrosion resistance and are easy to work with. They are lightweight and strong, making them ideal for construction and automotive applications. Cast alloys, particularly the 4000 series, have a higher silicon content. They can be more brittle but provide good fluidity, making them suitable for intricate designs. Choosing the right shredder involves considering the alloy type. Not every shredder can handle both categories efficiently.

You might realize that choosing the right equipment is not straightforward. Each type of alloy has specific shredding requirements. A shredder that handles wrought alloys may struggle with cast materials. Thus, assessing the alloy type and your processing needs is vital. Sometimes, it feels overwhelming, but understanding these distinctions leads to better decisions.

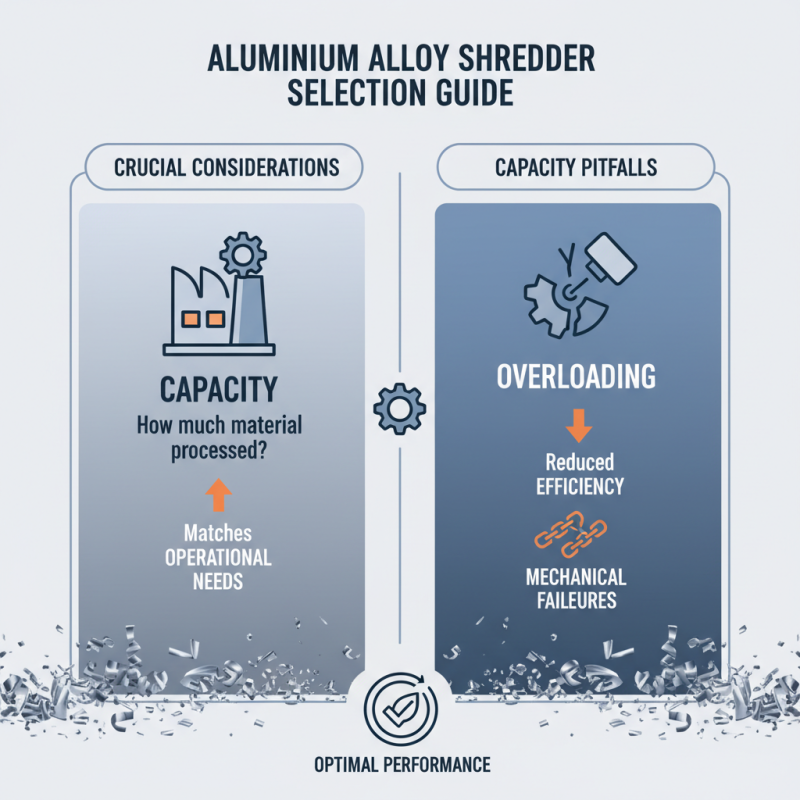

When selecting an aluminium alloy shredder, it’s vital to consider key features that fit your operational needs. The shredder's capacity is crucial. It determines how much material can be processed at once. A shredder with a large capacity may seem ideal but can lead to issues. If you overload it, you may face mechanical failures or reduced efficiency.

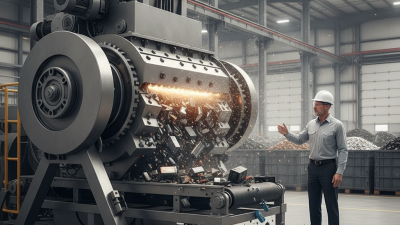

Another aspect to look for is the cutting mechanism. A quality shredder should have durable blades that resist wear and tear. Sharp blades improve shredding efficiency and produce finer particles. However, maintenance is often overlooked. Regularly inspecting and replacing blades can be burdensome but is necessary for optimal performance.

Power consumption is another significant factor. A shredder that uses excessive energy can increase operational costs. Look for a model that balances power and efficiency. Some machines may promise high performance but at a cost. Reflect on whether you truly need such capabilities. Assessing your specific needs can prevent unnecessary investment in features you may not utilize fully.

When choosing an aluminium alloy shredder, understanding your volume and frequency requirements is crucial. According to recent industry reports, demand for aluminium recycling machines has surged, driven by sustainability initiatives. In North America, for instance, the recycling rate of aluminium is approximately 75%. This statistic highlights the importance of efficient shredding machinery.

Aligning your shredder choice with your operational demands is essential. If you process large quantities of aluminium daily, a high-capacity model is needed. For example, shredders with throughput rates exceeding 5 tons per hour are ideal for heavy-duty operations. In contrast, smaller businesses might only need machines that handle one to two tons per hour. Assess how often you generate scrap materials. If your frequency is high, investing in a more robust machine will enhance productivity.

Consider possible pitfalls in your decision-making process. Oversizing your shredder can lead to wasted resources. The initial cost might be higher than anticipated, impacting budgets. Conversely, a shredder that is too small can result in downtime and operational challenges. Balancing these factors requires careful planning and foresight. Taking the time to analyze your specific needs can lead to a more effective investment.

When selecting an aluminium alloy shredder, maintenance and durability are crucial factors. Regular maintenance can extend the lifespan of your machine. It often involves simple tasks like cleaning, lubrication, and parts replacement. Ignoring these tasks can lead to costly repairs.

Consider how often you will use the shredder. If it’s for heavy-duty tasks, investing in a model with robust components is wise. You want a machine that can withstand the rigors of daily use. It’s vital to assess the build quality. Thinner materials could wear out faster.

Tips: Always check the shredder’s manual for maintenance guidelines. Keeping a maintenance log can help track when parts were last serviced. Make sure you have access to necessary tools for repairs. This proactive approach saves time and money in the long run.

Sometimes, you might overlook small issues. These can escalate into larger problems later. Regular checks can prevent unexpected breakdowns. A vigilant eye on the equipment can pay off handsomely. Remember, a durable shredder is a sound investment.

Choosing the right aluminium alloy shredder can be tricky. One of the most critical factors is the budget. You might think you need the latest technology, but sometimes simpler models suffice. Expensive options often offer features you may never use. Focus on what fits your specific needs.

Cost and functionality should align. A higher price rarely guarantees better performance. Look for essential features like capacity and speed. But don’t ignore the maintenance costs. Some models require more upkeep, which adds to the overall expense over time.

Consider the potential hidden costs. You may find an affordable shredder but discover replacement parts are pricey. Evaluate whether the shredder meets your production goals without breaking the bank. It’s easy to overlook these details when making a fast decision. Reflect on your needs carefully before making a purchase.