Choosing the right Tire Shredding Machine can transform your recycling operation. According to industry expert John Thompson, "The right machine can make all the difference in efficiency and output." Selecting a Tire Shredding Machine involves critical considerations. You must assess your production capacity and material types.

Different machines offer varying features and capabilities. Some models are compact, ideal for small operations. Others are larger and can handle high volumes. This diversity can be overwhelming. Experts suggest evaluating your specific needs first before making a decision.

Some machines may seem cost-effective but lack durability. This could lead to higher long-term costs. Reflecting on operational goals is essential. Each choice impacts profitability and production quality. This decision isn't just a financial one; it’s about sustainable practices too. In the world of recycling, a reliable Tire Shredding Machine is key to success.

When exploring tire shredding machines, understanding the various types available is crucial. These machines often fall into categories based on design and capacity. For example, some are single shaft shredders while others are dual shaft. Each type serves a unique purpose and varies in output size. Single shaft machines typically provide a finer shred, while dual shaft models excel in handling tougher materials.

Another important factor is the size of the tires they can process. Some machines handle larger tires better, while others are more efficient with smaller ones. The feed mechanism also differs. Some machines have a hydraulic feed, while others rely on gravity. This can affect the production speed and efficiency. Focusing on your specific needs will help filter your choices.

Consider the maintenance requirements as well. Some machines need frequent checks and part replacements, which can be time-consuming. Are you prepared for this commitment? The cost of operation is also a factor. Energy consumption can vary significantly. Can your budget accommodate the ongoing costs? Reflecting on these points will help you make a more informed choice.

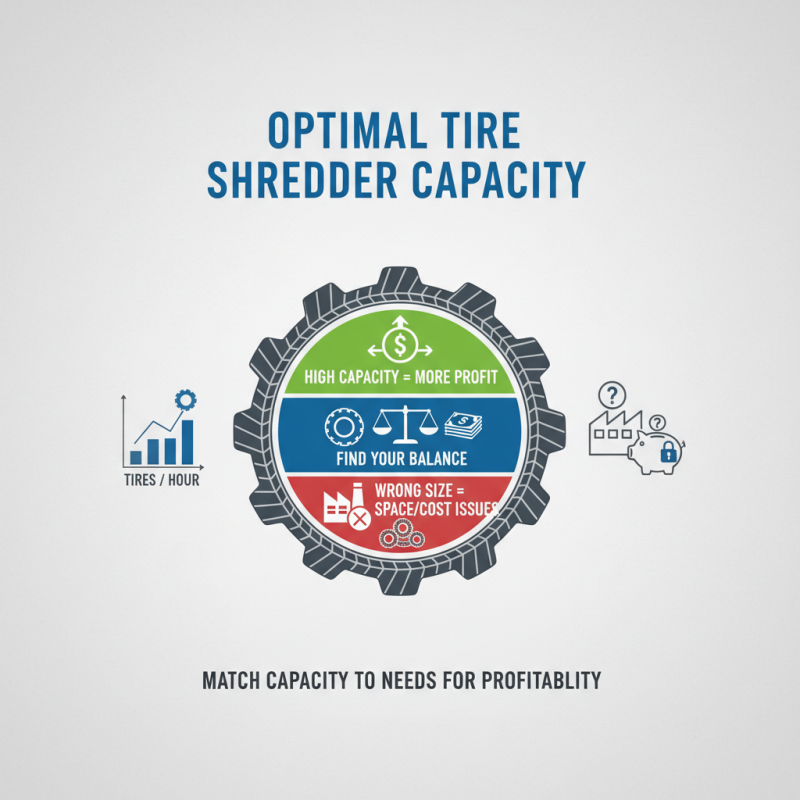

Choosing the best tire shredding machine can be overwhelming. Several key factors will guide your decision-making process. Start with the machine's capacity. Consider how much rubber you intend to shred daily. A small machine may struggle with larger volumes. Always match the machine's output to your needs.

Next, focus on the shredding technology. Different machines use various methods. Some might produce finer shreds, while others create larger pieces. Assess the end product you require. Also, consider operating costs. Maintenance and energy consumption can add up quickly. Look beyond the purchase price.

Don't forget safety features. A machine with inadequate safety measures could pose risks. Review user feedback on safety protocols. Make sure you understand the operation guidelines as well. This knowledge is crucial to avoid accidents. There may be a learning curve. Be ready to adapt and refine your approach.

This chart compares two different tire shredding machines based on key features such as processing capacity, power consumption, initial cost, maintenance cost, and noise level. This information can help you make an informed decision when choosing the best tire shredding machine for your needs.

When choosing a tire shredding machine, assessing production capacity is crucial. The production capacity dictates how many tires you can process per hour. A higher capacity can lead to increased profitability. However, a machine that is too large may not fit your space or budget. You need to find a balance that suits your operational needs.

Efficiency is another key element. A machine that runs smoothly can save time and reduce costs. Look for features that enhance performance, like sharp blades and sturdy construction. These elements can affect your overall output. Sometimes, it’s beneficial to prioritize features over sheer capacity. An efficient smaller machine may outperform a larger, inefficient one in the long run.

Consider the specific requirements of your project. You may need a machine that adjusts to different tire sizes. Not all machines offer this flexibility. Additionally, reflect on the maintenance aspect. Some models require more upkeep than others. This could impact your efficiency over time. It's essential to evaluate both current and future needs carefully. Making a rushed decision can lead to problems down the line.

When choosing a tire shredding machine, safety features are crucial. Look for machines with protective guards. These can prevent injuries during operation. Emergency stop buttons are also vital. They allow operators to halt the machine quickly in emergencies. Another essential feature is noise reduction. High noise levels can lead to hearing damage. A quieter machine ensures better working conditions.

Maintenance needs are equally important. Machines should have easy access points for cleaning and repairs. Consider machines that offer clear maintenance guidelines. Regular inspections can help identify wear and tear early. Look for user-friendly interfaces to simplify routine checks. This reduces the chances of overlooking critical maintenance tasks.

A good tire shredding machine should balance efficiency and safety. Don’t focus solely on speed; remember that a safe machine is a productive one. Evaluate your options carefully. Each feature plays a role in the overall performance and longevity of the equipment. Choosing wisely can save time and money down the road.

When considering tire shredders, costs are a primary factor. Your budget will dictate the options available to you. Prices for tire shredding machines can vary significantly. Factors include machine size, features, and processing capacity. Smaller, basic models may be less expensive but might not meet your requirements. Larger machines with advanced features could be beneficial but come with higher costs.

It's crucial to evaluate the total cost of ownership. Maintenance fees, energy consumption, and replacement parts can add up over time. A cheaper initial price does not always equate to savings. Investing a bit more upfront can lead to lower long-term costs.

**Tips:** Think about your production needs. A machine that suits your current demands may not suffice in the future. Research different models and read user reviews. Make sure to factor in potential downtime. Waiting for repairs can be expensive. Always get a sense of the warranty offered. This can save you money if issues arise. Each detail matters, so take your time in choosing.

| Feature | Entry-Level Model | Mid-Range Model | High-End Model |

|---|---|---|---|

| Initial Cost | $20,000 | $50,000 | $100,000 |

| Processing Capacity (tons/hour) | 2 | 5 | 10 |

| Power Consumption (kW) | 15 | 30 | 50 |

| Maintenance Cost (annual) | $2,000 | $5,000 | $10,000 |

| Average Lifespan (years) | 5 | 10 | 15 |

| Operator Skill Level | Basic | Intermediate | Advanced |