In today's fast-paced industrial landscape, the selection of an appropriate Circuit Board Breaker is critical for ensuring safety and reliability in electrical systems. According to a report by MarketsandMarkets, the global circuit protection market is projected to reach $34.58 billion by 2025, driven by increasing safety regulations and the rising demand for efficient power management solutions. With diverse applications ranging from automotive to aerospace, the choice of the right Circuit Board Breaker not only impacts the operational efficiency of electronic devices but also adheres to essential industry standards.

By understanding the key factors and considerations for selecting these breakers, industry professionals can enhance their system's performance while mitigating potential risks associated with electrical failures. This guide presents five essential tips to help you navigate the complexities of choosing the right Circuit Board Breaker tailored to your specific industry needs.

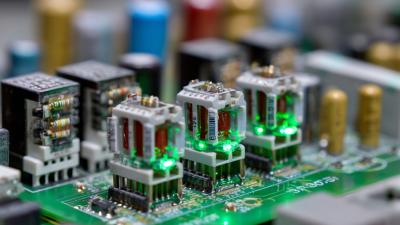

When selecting circuit breakers for industrial applications, understanding the various types available is crucial for ensuring safety and efficiency. Circuit breakers play a vital role in protecting electrical circuits from overloads and short circuits. The most common types include thermal magnetic,Electronic, and ground fault circuit breakers, each suited for different operational requirements. Thermal magnetic breakers are ideal for general-purpose applications, while electronic breakers provide precise protection settings, making them suitable for sensitive equipment.

Tip 1: Consider your specific application requirements before choosing a breaker. For example, if your equipment is prone to needing high startup currents, a breaker designed for such demands will perform better and prolong the lifespan of your machinery.

Another important aspect is the breaker’s trip characteristics. Tip 2: Match the trip curve of the circuit breaker to the load you are protecting. A slow trip curve is preferable for inductive loads, while a fast trip is suitable for resistive loads. This tailored approach reduces the chances of nuisance tripping while ensuring reliable operation under fault conditions.

| Type of Circuit Breaker | Key Features | Industry Standards | Typical Applications | Voltage Rating |

|---|---|---|---|---|

| Thermal Circuit Breakers | Current sensing, Manual reset | UL 489, ISO 9001 | HVAC systems, Compressors | 120/240V |

| Magnetic Circuit Breakers | Instantaneous trip, No moving parts | IEC 60947-2 | Molded Case Switch, Power tools | Up to 600V |

| Ground Fault Circuit Interrupters (GFCI) | Leakage detection, Fast response | NFPA 70, UL 943 | Outdoor circuits, Wet environments | 120V |

| Residual Current Devices (RCD) | Earth leakage protection, Manual reset | IEC 61008 | Residential services, Commercial areas | 230/400V |

| Air Circuit Breakers (ACB) | High current, Remote operation | IEC 60947-2 | Industrial applications, Bus ducts | Up to 1000V |

When selecting circuit board breakers, it is essential to consider key industry standards that ensure safety and reliability. One of the primary standards to keep in mind is the National Electrical Manufacturers Association (NEMA) ratings, which classify the suitability of circuit breakers for various environments. These ratings help determine the durability and appropriate applications of the breakers, including their resistance to moisture, dust, and other contaminants. Ensuring that the breaker meets NEMA ratings relevant to your specific industry can prevent malfunction and enhance safety.

Another critical standard is the International Electrotechnical Commission (IEC) guidelines, which focus on the global standard for electrical equipment. The IEC standards provide parameters for testing and performance, ensuring that circuit board breakers operate efficiently under different electrical load conditions. Compliance with these standards not only guarantees product quality but also facilitates international compatibility, making it easier to source and replace components in a global market. Choosing circuit board breakers that adhere to both NEMA and IEC standards can significantly enhance operational safety and efficiency in your applications.

When selecting a circuit board breaker, understanding current ratings and voltage levels is crucial for ensuring optimal performance. According to the NEMA, the right breaker should not only match your circuit's nominal voltage but also accommodate surges and fault conditions. Current ratings, measured in amperes, directly influence the breaker's ability to handle electrical loads without tripping. For instance, a breaker rated for a higher current than your application needs may not trip as intended during an overload, potentially leading to overheating and failure.

When evaluating your options, consider the following tips. First, assess your system's maximum load to choose a breaker that can handle it effectively without unnecessary tripping. Second, refer to industry standards, such as IEC 60947-2, which emphasizes the importance of selecting a breaker that aligns with both operational and environmental factors. Additionally, voltage levels must be checked against the specifications of your circuit. For example, using a breaker rated for 240V in a 120V circuit might lead to inefficiencies or safety hazards.

By thoroughly evaluating these factors and adhering to established industry standards, you can select the most suitable circuit board breaker that enhances reliability and performance within your electrical system.

When selecting a circuit board breaker, understanding environmental factors is crucial to ensure optimal performance and safety. Temperature fluctuations play a significant role; breakers must be rated for the operating temperature of their environment. For instance, high temperatures can lead to thermal overloads, while excessively low temperatures may impede the mechanical function of the breaker. Therefore, it’s essential to evaluate the typical temperature range and select a breaker that functions effectively within those limits.

Another critical environmental consideration is moisture and humidity. Circuit breakers located in damp or humid conditions require specialized ratings to prevent corrosion and electrical failures. Choosing breakers with an appropriate IP (Ingress Protection) rating can help safeguard against moisture intrusion. Additionally, exposure to dust and other particulates can affect the performance and longevity of circuit breakers. Ensuring that the selected breaker can withstand these environmental challenges is vital for maintaining circuit reliability and operational safety in various industrial applications.

When selecting a circuit board breaker, two pivotal factors to consider are cost and durability, which can significantly vary across different circuit breaker types. Traditional thermal-magnetic breakers, for instance, offer reliability at a lower cost but may not endure extreme conditions as well as contemporary electronic breakers. These newer models, while typically more expensive, provide enhanced precision and performance, making them suitable for applications that require robust protection and minimal downtime.

Additionally, understanding the specific requirements of your industry can guide your decision-making process. For example, in environments prone to moisture or dust, investing in more durable, weather-resistant breakers can mitigate long-term costs by reducing the frequency of replacements. Analyzing the long-term benefits of each type against their upfront costs can lead to a more informed choice, ensuring that the selected circuit breaker not only meets industry standards but also aligns with your operational goals and budget considerations.