In the realm of e-waste recycling, a Circuit Board Crusher plays a pivotal role. Experts emphasize its significance. For instance, Dr. Emily Tran, a leading figure in e-waste management, stated, "Efficient recycling starts with proper equipment." This highlights the need for specialized tools in tackling electronic waste.

With technology advancing rapidly, e-waste is becoming a pressing issue. Millions of tons of discarded electronics end up in landfills each year. The circuit boards within these devices contain valuable metals and hazardous materials. Without a Circuit Board Crusher, recycling becomes inefficient and often dangerous. The process requires precision and care to separate components safely.

Incorporating a Circuit Board Crusher into the recycling process streamlines operation. It enhances recovery rates, ensuring more materials are reused. However, many facilities still overlook this essential equipment. A lack of awareness creates a gap in effective recycling practices. Therefore, examining the role of the Circuit Board Crusher is crucial in promoting sustainable e-waste management.

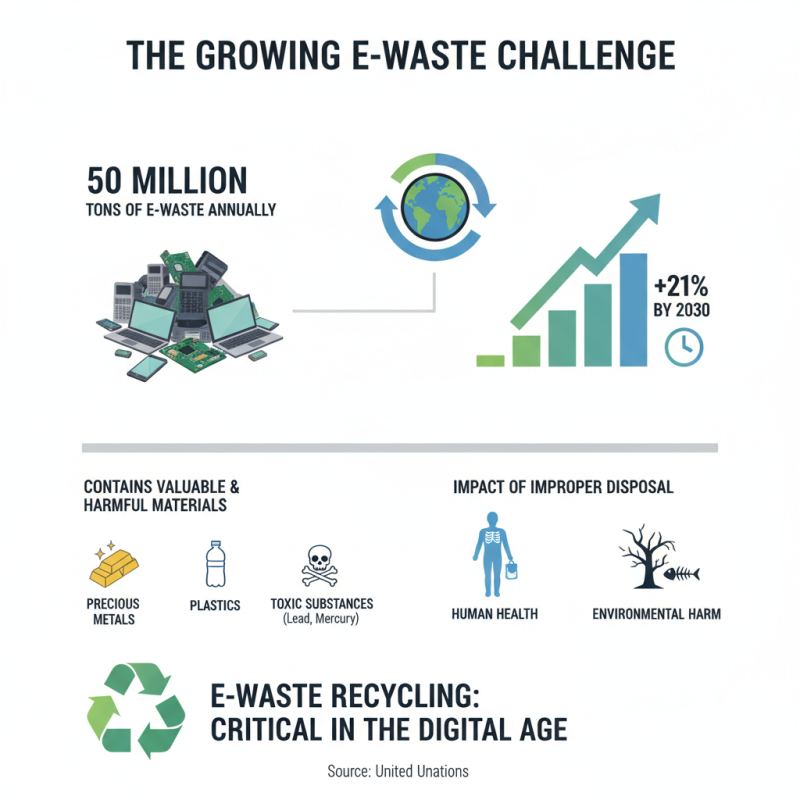

In today’s digital age, e-waste recycling is critical. According to the United Nations, around 50 million tons of electronic waste are generated each year. This figure is expected to increase by 21% by 2030. Electronic devices contain precious metals, plastics, and toxic substances. Improper disposal can harm both human health and the environment.

Circuit boards are a significant component of e-waste. They contain valuable materials like gold, silver, and copper. A study by the International Telecommunication Union reveals that recovering these materials can make a $62 billion industry. However, only 20% of e-waste is recycled properly worldwide. This gap presents a pressing challenge.

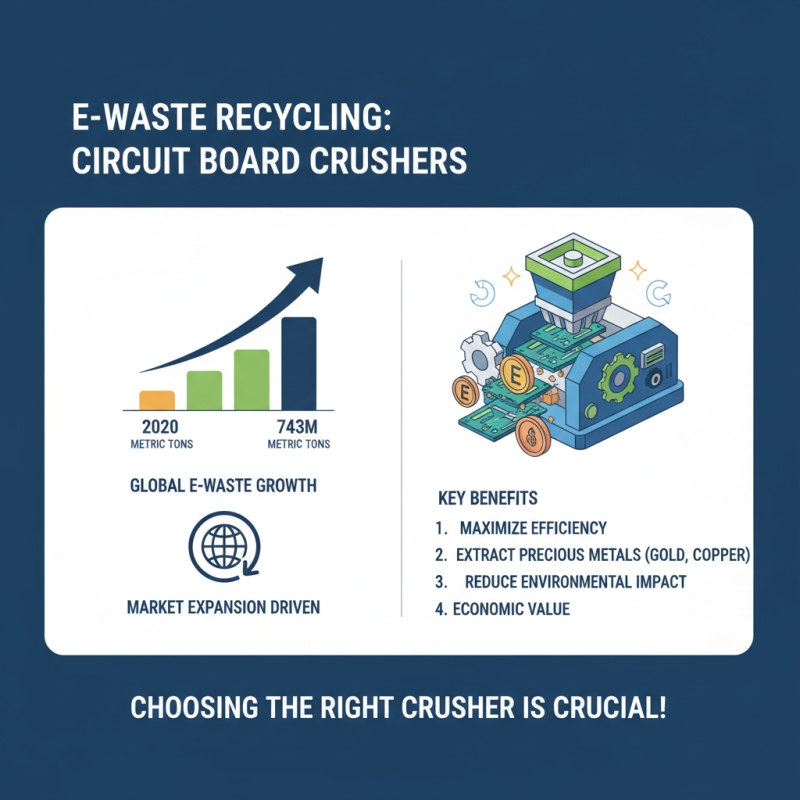

Recycling is not just about waste management. It's also about sustainable growth. Many organizations are focusing on circular economy strategies. Yet, the recycling process remains inefficient. A circuit board crusher enhances recovery rates, enabling better sorting and processing. Implementing more effective recycling methods can significantly minimize environmental risks. Each year wasted resources contribute to pollution and resource depletion. This reality calls for a robust response from industries and consumers alike.

Understanding circuit board components and their recyclability is crucial in e-waste recycling. Circuit boards contain valuable materials like gold, silver, and copper. These metals can be recovered and reused. However, not all components are recyclable. Some parts can be hazardous to the environment if simply discarded.

Tips: Always check local regulations on e-waste disposal. Certain components may require special handling. Proper sorting is essential before recycling.

Many circuit boards house microchips, resistors, and capacitors. These parts vary in their recyclability. A typical microchip often has low recovery rates. Some capacitors contain harmful substances, making them difficult to recycle. This complexity can lead to mistakes in the recycling process.

Tips: Educate yourself about which components can be recycled. Many organizations offer resources for this purpose. Avoid assuming that all electronic waste can be treated the same.

The role of circuit board crushers in e-waste processing is crucial. E-waste contains valuable metals, like gold and copper. A report by the United Nations states that around 50 million metric tons of e-waste is generated each year globally. Only 20% gets recycled properly. This gap shows the need for effective processing methods.

Circuit board crushers help in recovering these metals efficiently. They break down circuit boards into smaller pieces. This increases the surface area for metal extraction. A typical circuit board can contain up to 60% metals. However, untapped resources remain due to improper processing methods. Crushing these boards can lead to higher recovery rates.

Despite their benefits, there are challenges. Some recyclers lack the right technology. Others may not prioritize safety, leading to harmful emissions. It's essential to find a balance between efficiency and environmental responsibility. Effective recycling requires not just technology but a commitment to best practices. Finding solutions is an ongoing process in the industry.

E-waste recycling is a growing concern. Circuit boards contain precious metals like gold and copper. These are valuable, yet often wasted when discarded improperly. Using a circuit board crusher helps recover these materials effectively.

The environmental impact of e-waste is significant. Landfills overflow with toxic substances found in electronics. A circuit board crusher can reduce this waste. It breaks down boards into small pieces, making recycling easier and safer. This process minimizes pollution and conserves natural resources.

Employing these crushers also benefits the economy. Recovered materials can be repurposed, creating new products. This reduces the need for mining and promotes a circular economy. However, not all facilities have the right technologies. This gap needs addressing to maximize the benefits of e-waste recycling. Investing in efficient solutions is vital for a sustainable future.

Choosing the right circuit board crusher for e-waste recycling is crucial for maximizing efficiency. The market for electronic waste recycling is growing rapidly. Reports show that e-waste is expected to reach 74 million metric tons by 2030. A powerful circuit board crusher helps extract valuable metals like gold and copper from discarded electronics.

When selecting a crusher, consider the size of the circuit boards. Some machines handle larger boards while others focus on smaller ones. The capacity of the machine is equally important. Look for a model that can process your expected volume. Performance data shows that machines with higher throughput can save you time and operation costs.

Tips: Always check the energy consumption of the crusher. Lower energy use means better sustainability. Additionally, seek equipment that allows easy maintenance. Machines that are hard to service can become a burden over time.

It's important to conduct thorough research. Misleading specifications can lead to poor performance. You may find certain crushers underperforming in real-world scenarios. Take time to compare different models and seek reviews from users. This helps in making an informed decision. Remember, investing in the right crusher can significantly impact your recycling operation's success.