In the rapidly evolving electronics industry, the demand for efficient recycling technologies has become crucial. A Circuit Board Crusher serves as a vital tool in this recycling process. According to a recent market report by Research and Markets, the global circuit board recycling industry is projected to grow at a CAGR of 6.5% by 2028. This growth reflects the increasing need to recover valuable materials from electronic waste.

Dr. Emily Chen, a prominent expert in e-waste recycling, states, "The Circuit Board Crusher is essential for breaking down complex electronic components efficiently." This powerful machinery crushes printed circuit boards into smaller pieces, allowing for easier extraction of metals and other materials. As the amount of electronic waste rises, the relevance of such technology becomes more apparent.

However, challenges remain. Current crushers have limitations in handling varied circuit board types. Many machines struggle with non-standard components. This inconsistency can lead to lower recovery rates. As the industry pushes for innovation, the effectiveness of the Circuit Board Crusher must continually be assessed to meet future demands.

A circuit board crusher is a specialized machine designed to process electronic waste. It breaks down circuit boards into smaller pieces, aiding in the recovery of valuable metals. According to a report by Research and Markets, the global e-waste management market is expected to grow significantly, reaching $49 billion by 2025. This growth underscores the importance of efficient recycling methods, including circuit board crushing.

The process begins with the loading of circuit boards into the crusher. The equipment uses various mechanisms, like blades or hammers, to pulverize the boards. This shredding process turns large, complex components into manageable fragments. Notably, a study by the Global Recycling Foundation indicates that only 20% of e-waste is properly recycled. This fact raises questions about our current disposal practices and the efficiency of existing technologies.

After crushing, the material is further processed to separate metals from non-metallic substances. However, not all crushers are equally effective. Some may leave behind valuable materials, leading to waste. This reality shows a gap in the industry’s goal of maximizing resource recovery. Improving these machines can make a significant difference, but many challenges remain.

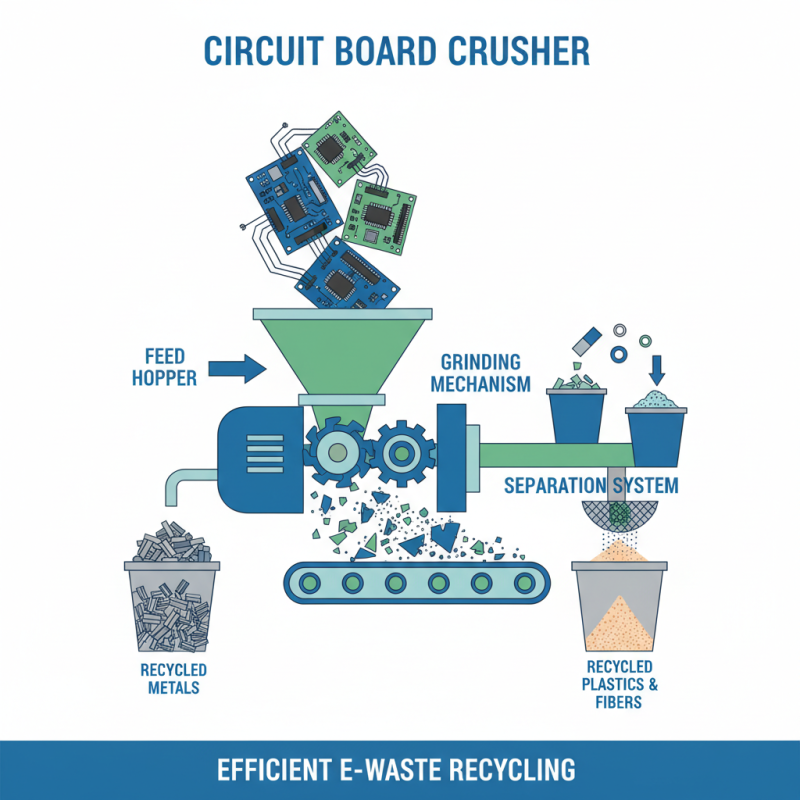

A circuit board crusher is an essential machine for recycling electronic waste. It breaks down circuit boards into smaller pieces efficiently. The primary components of a circuit board crusher include a feed hopper, grinding mechanism, and a separation system. Each part plays a critical role in the crushing process.

The feed hopper receives the circuit boards. Operators load the boards here. Once inside, the grinding mechanism takes over. It typically consists of rotating blades or hammers that shred the boards apart. The pieces become smaller as they pass through various stages. This method helps to recover valuable metals like copper and gold.

An effective separation system follows the grinding stage. It sorts the crushed material, dividing metals from non-metals. Magnets are often used to attract metallic shards. This process, while efficient, can sometimes miss small particles. A fine-tuning of the system is necessary for optimal recovery. Continuous improvements can lead to better yields in valuable materials.

Circuit board crushers operate through a systematic process designed to break down electronic waste efficiently. First, circuit boards are fed into the crusher, which uses powerful blades to shred them into smaller pieces. According to industry reports, this initial stage can reduce the board size by up to 90%. The smaller particles are crucial for the next steps in recovery and recycling.

Following the crushing, the debris undergoes separation. The materials are categorized into metals, plastics, and other components. Advanced magnets and air classifiers help in isolating valuable metals like gold and copper. For instance, studies show that nearly 50 million tons of e-waste are generated annually. A significant portion of this waste contains recoverable metals, making the separation process vital for resource recovery.

However, challenges remain in optimizing these processes. Some operators struggle with the efficiency of separating materials. A fundamental question arises: are we maximizing the resource recovery potential? Companies often need to refine their methods to enhance efficiency and reduce environmental impact. Without addressing these issues, the cycle of e-waste management may fail to meet future demands.

Circuit board crushers are essential tools in electronic waste management. These machines effectively shred circuit boards into smaller pieces, making it easier to recover valuable materials. The crushing process maximizes material recovery, enabling recyclers to obtain metals such as gold, silver, and copper. By breaking down the boards, crushers facilitate the separation of different materials for recycling. Using a circuit board crusher helps reduce environmental impact by minimizing waste in landfills.

The applications of circuit board crushers are varied. Recycling facilities utilize them for efficient processing of discarded electronics. Moreover, manufacturers can benefit by recycling obsolete devices internally. However, some challenges arise in ensuring that all materials are processed correctly. For instance, not all machines capture 100% of valuable components, leading to potential losses. There is also the need for proper maintenance to avoid operational failures. While circuit board crushers offer significant benefits, ongoing improvements in technology must continue to enhance performance and efficiency.

The environmental impact of circuit board crushers is significant. In electronic waste management, around 50 million metric tons of e-waste is generated annually. Circuit boards contain precious metals like gold, silver, and copper. These metals are crucial for recycling. However, improper disposal leads to toxic substances leaking into the soil and water.

Circuit board crushers play a vital role in this process. They help break down e-waste into smaller, manageable pieces. This makes it easier to extract valuable materials. According to industry reports, recycling can recover up to 90% of the metals in circuit boards. Yet, many facilities struggle with efficient recycling methods. About 80% of e-waste is still not recycled properly.

Despite advancements in technology, challenges persist. Not all circuit board crushers are created equal. Some produce harmful emissions during operation. This raises questions about their overall environmental footprint. Improvement in machinery design is essential. Effective recycling processes must limit toxins and maximize recovery rates. The potential for turning waste into resources is there, but action is needed.