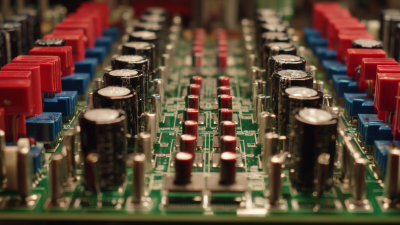

In the rapidly evolving world of electrical engineering, understanding the intricacies of Circuit Board Breakers is essential for ensuring safety and reliability in electrical systems. According to recent industry reports, nearly 30% of electrical failures can be attributed to malfunctioning circuit board breakers, underscoring the importance of addressing common issues and implementing effective solutions. Experts in the field, such as Dr. Emily Carter, a renowned electrical engineer, emphasizes this need by stating, "A well-maintained Circuit Board Breaker can significantly reduce the risk of electrical fires and system failures."

As technology advances, the demands on circuit board breakers continue to grow, leading to a myriad of potential issues that technicians must be prepared to tackle. From thermal overloads to mechanical failures, the ability to diagnose and rectify these problems promptly can mean the difference between a fully operational system and a complete shutdown. By exploring the top 10 common Circuit Board Breaker issues and their respective fixes, professionals in the field can equip themselves with the knowledge necessary to maintain high standards of performance and safety. This proactive approach is vital in an industry where precision is non-negotiable, highlighting the pivotal role of circuit board breakers in modern electrical applications.

Common circuit board breaker issues can significantly impact the functionality and safety of electrical systems. One of the primary problems is nuisance tripping, where breakers trip frequently without an actual overload. This can be caused by equipment malfunction, short circuits, or overloads due to multiple devices drawing power simultaneously. Identifying the root cause requires careful inspection of the electrical load and circuit paths to ensure they are operating within their rated capacities.

Another prevalent issue is a faulty breaker that fails to trip under overload conditions, which poses a serious safety risk. Regular testing and maintenance can help detect worn-out components that may not respond as they should. Additionally, physical damage to the circuit board, such as burn marks or cracks, is a critical problem that alters electrical flow. Repairing such damage often necessitates replacing the affected sections or the entire board. Ensuring a clean, dry environment and proper installation practices can help prevent these issues from arising, maintaining the integrity and safety of the electrical system.

Understanding circuit breaker ratings and specifications is crucial for both electrical safety and efficiency. Circuit breakers are designed to protect electrical circuits from overloads and short circuits, and their effectiveness largely depends on their ratings. The most important specifications to consider include voltage rating, current rating, and interrupting capacity. Voltage rating denotes the maximum voltage a breaker can handle, while current rating indicates the maximum current it can sustain without tripping. Interrupting capacity is the maximum fault current the breaker can safely interrupt, preventing damage to both the circuit and the breaker itself.

When choosing a circuit breaker, it’s essential to match these ratings with the specific requirements of your electrical system. For instance, a breaker with an insufficient current rating could fail to trip during an overload, posing risks of fire or equipment damage. Conversely, a breaker rated too high for the circuit could trip unnecessarily, causing disruptions. Additionally, understanding the specifications can aid in selecting the correct type of breaker for different applications, whether residential or commercial. Properly rated circuit breakers not only enhance safety but also increase the longevity and reliability of the electrical system.

Electrical overload is a common issue encountered in circuit breakers, often leading to significant operational downtime and safety hazards. According to industry reports, about 30% of electrical failures in commercial buildings are attributed to circuit breaker malfunctions stemming from overload situations. These failures can result from excessive current flow, usually exceeding the breaker's rated capacity, which can be caused by factors such as faulty appliances, circuit design flaws, or increased electrical demands during peak usage periods.

To effectively troubleshoot and mitigate electrical overload, it is crucial to first assess the load distribution across the circuit. Professionals recommend utilizing load calculators and monitoring tools to determine if the connected devices exceed the circuit's rated amperage. If overload is identified, solutions may include redistributing loads across multiple circuits, upgrading to higher-rated breakers, or installing dedicated circuits for high-demand equipment. The National Fire Protection Association (NFPA) highlights that properly managing electrical loads can reduce the risk of circuit breaker failure by as much as 50%, contributing to enhanced safety and reliability in electrical systems. Regular maintenance and periodic inspections are also indispensable to ensure the proper functioning of circuit breakers, reducing the likelihood of overload-related issues.

| Issue | Description | Symptoms | Solution |

|---|---|---|---|

| Overloading | Circuit breaker trips frequently due to too much load. | Lights flickering, appliances shutting off. | Distribute loads evenly or upgrade to a higher-rated breaker. |

| Short Circuit | Faulty wiring causing an immediate trip. | Burning smell, sparks, circuit trips instantly. | Inspect and repair wiring issues. |

| Ground Fault | Current leakage to ground. | Circuit breaker trips when using certain devices. | Install GFCIs in wet areas and check for appliance faults. |

| Faulty Breaker | Breakers wear out and malfunction over time. | Breakers that don’t reset or trip unnecessarily. | Replace the breaker with a new one. |

| Wiring Issues | Damaged or loose connections cause failures. | Flickering lights, tripped breakers. | Check and repair wiring connections. |

| Age of Breaker | Older breakers are less reliable. | Frequent issues without apparent cause. | Consider replacing older breakers as a preventive measure. |

| Environmental Factors | Moisture, dust can affect performance. | Corrosion, tripping events in damp conditions. | Ensure proper enclosure and conditioning for breakers. |

| Incorrect Breaker Size | Using a breaker that is too small for the load. | Frequent tripping, especially under heavy use. | Replace with a properly rated breaker for the load. |

| Loose Connections | Connections that become loose over time. | Intermittent power issues or tripping. | Tighten all connections and terminals. |

| Thermal Issues | Excessive heat can lead to breaker failures. | Smell of burning, breaker trips under load. | Ensure proper ventilation and cooling of electrical components. |

When dealing with circuit board issues, one of the most common problems is a short circuit. A short circuit occurs when the electrical current flows along an unintended path, often due to damaged components or faulty connections. This can lead to overheating, malfunctioning of devices, and ultimately, board failure. To identify a short circuit, visually inspect the board for burn marks or damaged components. Additionally, using a multimeter to test for continuity can help locate the issue. Once identified, replacing or re-soldering the faulty components is crucial for restoring functionality.

Tips: Always power down the board before inspection to avoid electric shocks. Make sure to use appropriate safety gear, such as gloves and goggles, when handling electronic components.

If you're unable to find the source of the short circuit, consider isolating sections of the board. Disconnect power to each section and test individually until the problematic area is identified. Once the cause is found, repair it by ensuring all connections are secure and components are properly seated. This systematic approach can prevent future occurrences and prolong the lifespan of your circuit board.

Tips: Keep a detailed log of any repairs made, as this can help in troubleshooting similar issues in the future. Regular maintenance checks can also catch potential problems early, ensuring reliable performance of your electronics.

This chart displays the frequency of common issues found in circuit board breakers, highlighting the importance of regular maintenance and issue identification.

Preventive maintenance for circuit board breakers is essential to ensure their longevity and reliable performance. Regular inspections can identify potential issues before they escalate into significant problems. Checking for loose connections, corrosion, or physical damage can save time and resources. Keeping components clean from dust and debris is also crucial, as contaminants can lead to overheating and eventual failure of the breakers.

Tips: Schedule routine checks every six months to evaluate the integrity of the circuit board. Use non-abrasive cleaning agents to remove dirt without damaging sensitive components. Additionally, ensure that all connections are tight, and consider applying protective coatings to prevent corrosion.

Another key preventive measure is updating firmware and software associated with circuit boards to benefit from the latest improvements and security fixes. Monitoring the operating environment—such as temperature and humidity—can greatly influence the lifespan of circuit board breakers. Implementing efficient airflow management and temperature controls will help maintain ideal conditions for the breakers.

Tips: Invest in environmental monitoring tools to keep track of temperature and humidity levels. When possible, implement redundant systems that can take over during maintenance or unexpected failures. Regularly review and update maintenance protocols to adapt to any changes in operational demands.