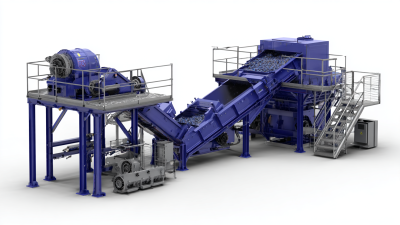

In today's world, the importance of recycling plastic cannot be overstated. A Plastic Recycling Grinder serves as an invaluable tool in this process. It transforms discarded plastics into smaller, manageable particles, paving the way for efficient recycling. However, using this equipment effectively requires knowledge and precision.

When operating a Plastic Recycling Grinder, attention to detail is crucial. Familiarize yourself with the settings and functionalities to optimize performance. Maintaining a steady workflow can be challenging. One must avoid overloading the grinder, as this can lead to poor results and equipment malfunction. Observing the grinding process closely allows for quick adjustments and better outcomes.

Additionally, it is essential to remember that not all plastics are created equal. Different types may require different approaches. Understanding these nuances will enhance efficiency. Yet, even seasoned operators may face setbacks. Reflecting on these experiences can lead to improved techniques in the long run. Embracing the learning process emerges as a vital aspect of mastering the Plastic Recycling Grinder.

A plastic recycling grinder plays a crucial role in the recycling process. These machines efficiently break down plastic waste into smaller pieces, allowing for easier sorting and processing. According to recent industry reports, utilizing grinders can increase the efficiency of recycling facilities by up to 30%. Understanding their functionality is key to maximizing this advantage.

To use a plastic recycling grinder effectively, focus on material preparation. Ensure the plastic is clean and free from contaminants. Contaminated materials can lead to poor grinding performance and lower quality recycled products. Remember, the input materials can significantly impact the output quality.

Another tip involves regularly maintaining your grinder. Regular checks can prevent unexpected breakdowns and ensure smooth operation. Maintain sharp blades for optimal grinding. Dull blades require more energy and create uneven particle sizes. This can affect the recycling quality. Aim for consistency in particle size to enhance downstream processing.

Choosing the right type of grinder for your recycling needs is crucial. Low-quality grinders can lead to inefficient processes and increased material waste. Research shows that about 25% of recycled plastic is lost due to inadequate grinding techniques.

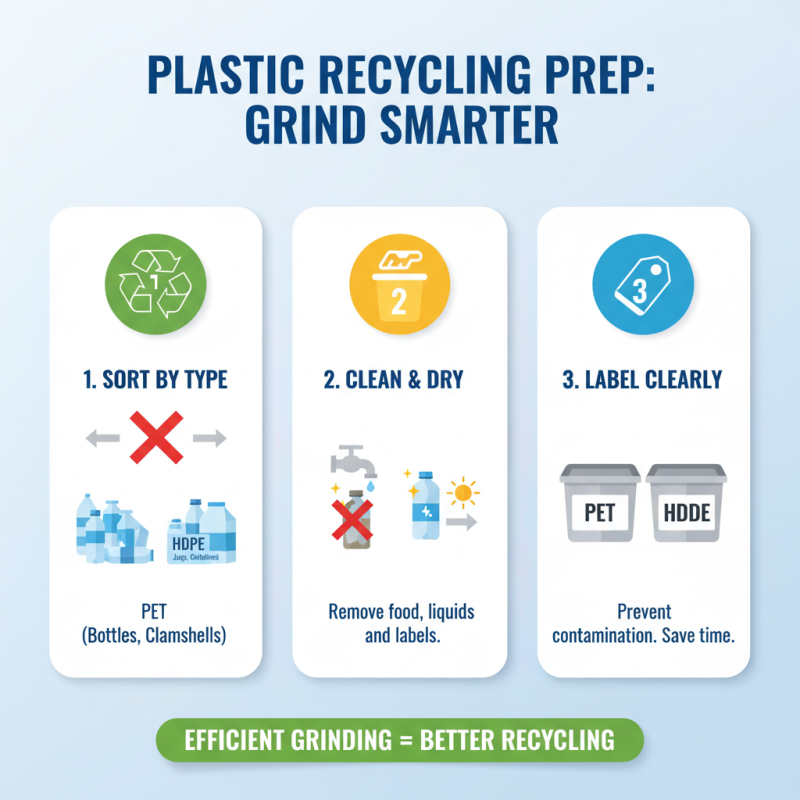

When selecting a grinder, consider the type of plastic you will process. Different materials, like PET or HDPE, require specific grinding capabilities. A grinder that excels in one area may fall short in another. Analyze your recycling goals to ensure compatibility.

Tip: Regular maintenance of the grinder is essential. Sharpening blades and cleaning the machine can boost efficiency. Additionally, testing different settings can optimize results. Don't overlook the importance of operator training. Lack of knowledge can lead to errors and wasted resources.

Remember that choosing a grinder is not just a financial decision. The impact on the environment should weigh heavily in your choice. Data indicates that proper recycling reduces landfill waste by over 20%. It's not merely about spending money; it's an investment in sustainability.

| Tip Number | Tip Description | Grinder Type Suggested |

|---|---|---|

| 1 | Choose a grinder with an adjustable screen for different particle sizes. | Versatile Grinder |

| 2 | Regularly maintain the blades for optimal performance. | Heavy-Duty Grinder |

| 3 | Utilize a feed hopper to improve efficiency during grinding. | Industrial Grinder |

| 4 | Opt for a grinder with powerful motor for large volume processing. | Commercial Grinder |

| 5 | Select a grinder that minimizes noise and vibration for safer operation. | Silent Operation Grinder |

| 6 | Ensure easy access for cleaning and maintenance tasks. | User-Friendly Grinder |

| 7 | Look for grinders with safety features to protect operators. | Safety-Enhanced Grinder |

| 8 | Evaluate the energy consumption to optimize operational costs. | Eco-Friendly Grinder |

| 9 | Consider the size and portability for your workspace layout. | Portable Grinder |

| 10 | Research user reviews and ratings for performance insights. | Top Rated Grinder |

Proper preparation of materials is vital for efficient grinding and recycling plastic. Begin by sorting plastics based on their type. Different plastics, like PET and HDPE, have distinct properties. Mixing them can lead to poor grinding results. Label your sorted piles clearly to reduce confusion. This step saves time during the grinding process.

Cleaning the plastics is another crucial task. Residue from labels, food, or chemicals can affect the quality of the grind. Rinse off visible dirt and contaminants. Dry the materials before grinding to avoid clogs in the machine. It may seem tedious, but this effort improves efficiency significantly.

Despite thorough preparation, issues might still arise. Sometimes, materials may block the grinder. Be ready to pause and inspect regularly. Not all plastics grind the same way. Some might require multiple passes. Understanding these nuances can lead to a smoother process. Refinement and adjustment are part of the journey in recycling.

Proper maintenance of your plastic recycling grinder is crucial. Regularly check the blades for wear and tear. Replace dull or damaged blades to ensure efficient grinding. Clean the grinder thoroughly after each use. Plastic residue can build up and affect performance. Use a brush to remove leftover materials from all crevices.

Lubricate moving parts to prevent rust and ensure smooth operation. Over time, dust and particles can clog the grinder. Inspect and clear any blockages as needed. Monitor the motor for overheating. If it feels too hot, pause and allow it to cool. This simple step can extend the lifespan of your equipment.

Make it a habit to store the grinder in a dry place. Humidity can lead to rust and malfunction. Document any issues you encounter. Reflect on recurring problems and find solutions. Regular maintenance not only enhances performance but also saves money in the long run. Pay attention to these details to keep your grinder running efficiently.

When using a plastic recycling grinder, safety should be your top priority. According to the Environmental Protection Agency, grinding can generate hazardous dust and particles. Wearing protective gear is crucial. Safety goggles and masks can help shield you from flying debris. Gloves are essential for preventing injuries.

Ensure your workspace is organized. Clutter can lead to accidents. Keep the area dry to avoid slip hazards. Regularly inspect your grinder for any defects. A malfunctioning machine can cause serious injuries. Statistics show that improper maintenance is a common cause of workplace injuries in recycling.

Be cautious with plastic materials. Some plastics can release harmful fumes when heated. Always work in a well-ventilated area. Monitoring the grinding temperature is also key. An overheated grinder can malfunction. These steps might seem simple, yet they are often overlooked. Reflecting on your practices can lead to safer outcomes.