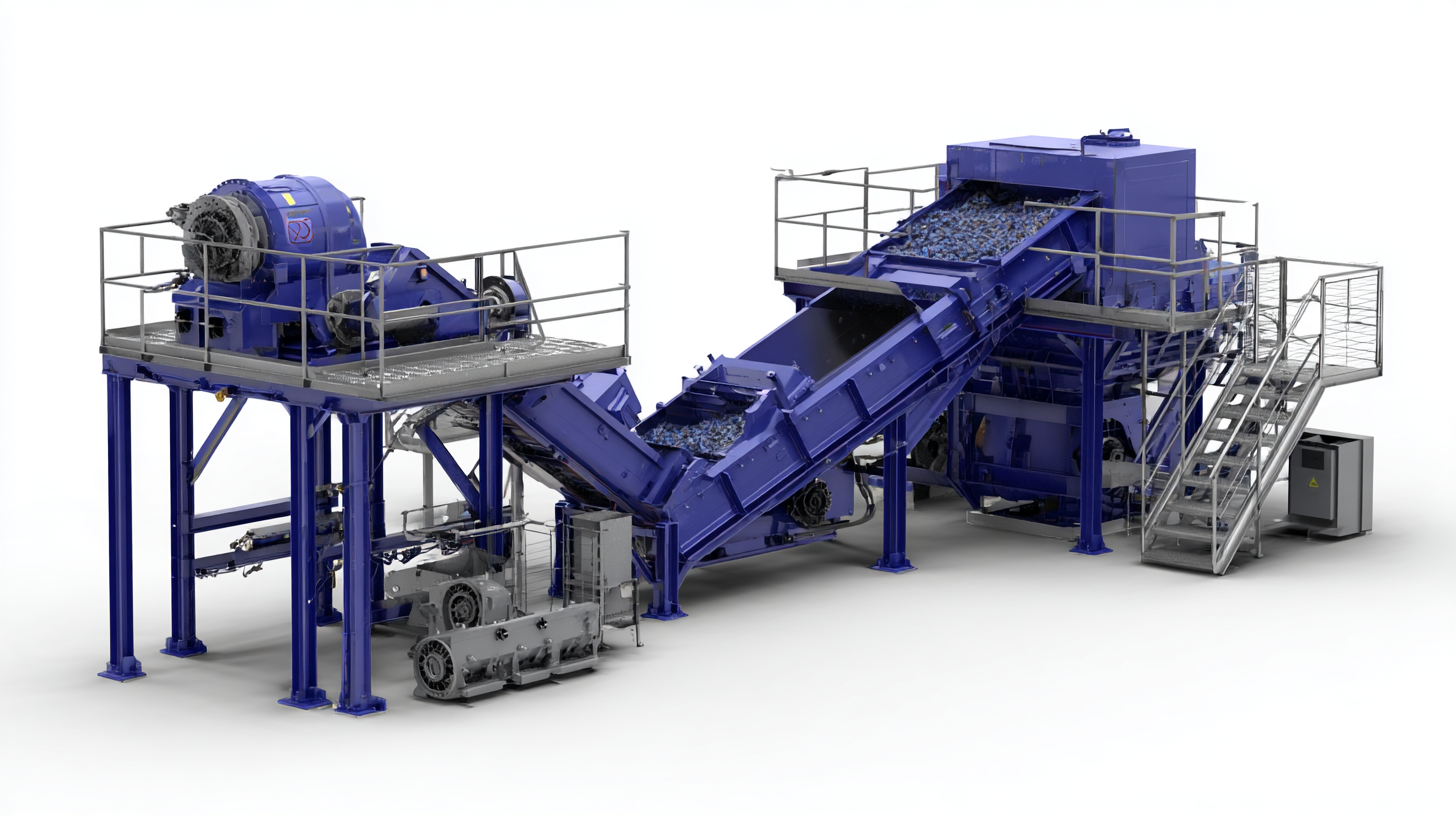

In the rapidly evolving landscape of waste management, the emergence of innovative solutions such as the Hdpe Shredder Machine is set to revolutionize recycling practices by 2025. As plastic waste continues to pose significant environmental challenges, the need for efficient and effective recycling methods has never been more critical.

The Hdpe Shredder Machine, designed to process high-density polyethylene materials, not only streamlines waste reduction efforts but also enhances the quality of recycled products. This blog will delve into the intricate technical specifications of these advanced machines, exploring their capabilities and features. Additionally, we will provide a comprehensive guide on how to integrate Hdpe Shredder Machines into current waste management systems, ensuring a sustainable future for recycling.

Join us as we explore the transformative potential of these machines and their impact on the recycling industry.

As we look towards 2025, the evolution of HDPE shredder machines is poised to revolutionize the recycling landscape. When selecting a shredder, several key features will significantly enhance efficiency and sustainability. First, energy efficiency is paramount; advanced machines that utilize less power while maximizing output will not only reduce operational costs but also lower carbon footprints. Investing in models that incorporate smart technology can provide real-time data on performance and help optimize processes.

Another critical aspect to consider is blade design and durability. High-quality, interchangeable blades made from resilient materials are essential for handling various types of HDPE waste. This adaptability allows for a more versatile recycling operation, catering to diverse business needs. Moreover, user-friendly controls and automation features will simplify operation, enabling facilities to increase throughput while maintaining safety and compliance. As we prepare for the near future, these innovations will be fundamental in shaping a more effective and environmentally conscious approach to waste management and recycling.

This chart illustrates the projected improvements in various key performance metrics for HDPE shredder machines by the year 2025. Notably, efficiency is expected to see the highest impact, followed by cost reduction, indicating a significant transformation in the recycling process.

The waste management industry is on the cusp of a transformation, thanks in part to the emergence of advanced technologies like HDPE shredders. High-Density Polyethylene (HDPE) is one of the most commonly recycled plastics, and its efficient processing is critical for sustainable recycling practices. The latest HDPE shredder machines are engineered to maximize throughput and minimize energy consumption, which makes them essential for modern recycling facilities. These machines not only streamline the shredding process but also enhance the quality of reclaimed material, paving the way for increased recycling rates and reduced environmental impact.

Moreover, the role of HDPE shredders extends beyond mere destruction of plastic. They serve as a catalyst for innovation in the recycling sector, spurring the development of new materials and products. As industries seek to move towards a circular economy, HDPE shredders offer a scalable solution that can adapt to varying types and volumes of waste. The integration of smart technology into these machines also promises to improve operational efficiencies, enabling real-time monitoring and predictive maintenance. As we head towards 2025, the proliferation of HDPE shredders will undoubtedly reshape the landscape of waste management, making recycling more accessible and effective than ever before.

The recycling landscape is rapidly evolving, and HDPE shredder machines are at the forefront of this transformation. These advanced machines play a critical role in enhancing the efficiency of recycling processes, particularly for post-consumer plastics. With the increasing volume of polymer waste, the need for effective shredding and dewatering solutions is more crucial than ever. Innovative technologies in shredding not only simplify the separation of materials but also optimize the subsequent recycling stages.

Recent advancements demonstrate significant success stories, such as the operations at a plastics recycling facility in the Netherlands, where dedicated machines efficiently process HDPE and polypropylene waste. This focused approach has led to streamlined operations, reduced processing times, and improved material recovery rates. Furthermore, companies in Texas have reported remarkable achievements by integrating modern shredding technologies, achieving dramatic reductions in landfill costs and significantly boosting employee productivity. As the recycling industry continues to seek ways to enhance efficiency, HDPE shredder machines will undoubtedly play a vital role in shaping sustainable practices by 2025 and beyond.

The advanced HDPE shredder machines are set to revolutionize waste management and recycling efforts by 2025. By efficiently breaking down high-density polyethylene (HDPE) waste materials, these machines significantly enhance the recycling process. With the increasing amount of plastic waste generated globally, their role in reducing landfill contributions becomes vital. By optimizing the shredding process, these machines not only prepare HDPE for further recycling but also facilitate the recovery of valuable materials that can be reintroduced into the manufacturing cycle.

Moreover, the environmental impact of advanced HDPE shredders extends beyond mere efficiency. These machines contribute to substantial waste reduction, further mitigating the strain on local ecosystems caused by improper disposal practices. By enabling the transformation of waste into reusable resources, the shredders drive a circular economy, promoting sustainability and reducing the carbon footprint associated with producing new plastic materials. The integration of innovative technologies in waste management thus heralds a greener future, emphasizing the importance of proper recycling solutions in combating environmental challenges.

| Aspect | Value | Impact |

|---|---|---|

| Waste Reduction Rate (%) | 50% | Decreased landfill usage |

| HDPE Recycling Rate (%) | 70% | Increased material recovery |

| Energy Savings (kWh/kg) | 1.2 kWh | Reduced carbon footprint |

| Reduction in Greenhouse Gas Emissions (CO2 tons/year) | 30,000 tons | Mitigation of climate change |

| Job Creation (number of jobs) | 5,000 jobs | Economic growth and community development |

| Projected Market Growth (%) | 15% | Increased investment in technology |

In recent years, the integration of shredders into the waste management sector has become a crucial aspect of establishing a circular economy. By enhancing the efficiency of recycling processes, advanced shredding technologies can significantly reduce the volume of solid waste and transform materials into reusable resources. This aligns perfectly with the global rush towards sustainability, particularly as countries like China ramp up their efforts to digitalize waste management practices by 2025.

One of the essential tips for effective waste management is to prioritize the source separation of materials. By educating communities about sorting recyclables at the origin, we can accelerate the shredding and recycling process, ensuring that high-quality materials are fed back into the economy. Furthermore, embracing automation and digital tracking can optimize the logistics of waste collection and processing, paving the way for improved material recovery rates.

Another helpful strategy is to foster collaboration between industries and governments. By sharing best practices and innovations in HDPE shredding and other recycling technologies, stakeholders can enhance their contributions to a circular economy. Encouraging public-private partnerships can also facilitate investments in green technology, driving progress toward sustainable waste management solutions that support both local economies and global environmental goals.