In today's rapidly evolving technological landscape, the importance of adhering to global industry standards for Circuit Board Breakers cannot be overstated. According to a recent industry report by MarketsandMarkets, the global circuit breaker market is projected to reach $15.6 billion by 2025, highlighting the increasing reliance on reliable electrical components in both residential and commercial applications.

With the surge in demand for renewable energy sources and smart grid technologies, understanding the intricacies of industry certifications has become paramount. Certifications not only ensure compliance with safety and performance requirements but also facilitate smooth international trade. As organizations aim to streamline their processes while maintaining the highest quality standards, it is essential to comprehend how these certifications impact the import and export of Circuit Board Breakers and which best practices can be implemented to navigate this complex landscape efficiently.

The world of circuit board breakers is governed by a set of robust global industry standards that ensure safety, efficiency, and reliability. These standards, developed by various international organizations, serve as benchmarks for manufacturers and users alike, helping to maintain uniformity across different regions and applications. Notable standards such as IEC 60947-2 and UL 489 play crucial roles in defining the performance requirements and testing procedures for circuit breakers, facilitating a common understanding among stakeholders.

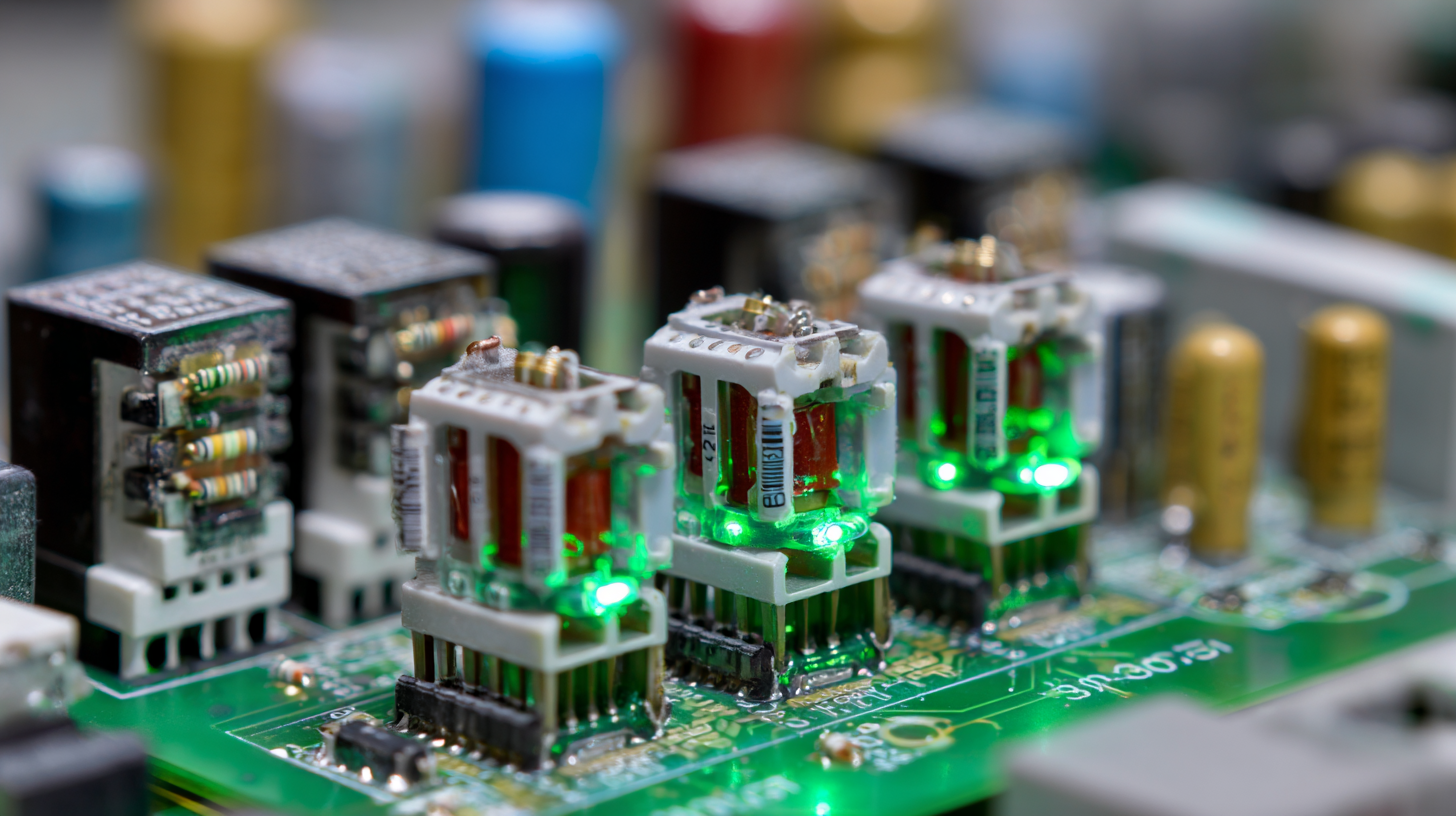

One of the key aspects of these standards is that they address the diverse operating environments and electrical demands faced by circuit breakers in various applications. This includes specifications on materials, thermal and mechanical endurance, and fault current interruption capabilities. Compliance with these standards not only enhances product safety but also ensures compatibility with other equipment, paving the way for seamless integration in complex electrical systems. By adhering to global industry standards, manufacturers can deliver high-quality circuit board breakers that meet the rigorous demands of modern electrical infrastructure.

When it comes to circuit board breakers, understanding key specifications and features is crucial for ensuring reliability and performance. Effective circuit board breakers are designed to protect electrical circuits from overloads and short circuits, safeguarding sensitive components. One primary specification is the Interrupting Rating, which indicates the maximum fault current the breaker can handle without failing. Choosing a breaker with an adequate rating minimizes risks during unexpected surges, thereby maintaining uninterrupted operation.

Another vital feature to consider is the trip curve, which defines the response time of the breaker under different load conditions. Breakers are available in various trip characteristics—such as B, C, and D curves—each suited for different applications. For instance, a C curve breaker is ideal for circuits with moderate inrush currents, providing reliable protection without nuisance tripping. Additionally, the size and mounting style of the breaker play a significant role in its installation flexibility within circuit boards.

Compact designs that can easily integrate into various layouts are preferred for modern electronics, ensuring efficiency without compromising safety.

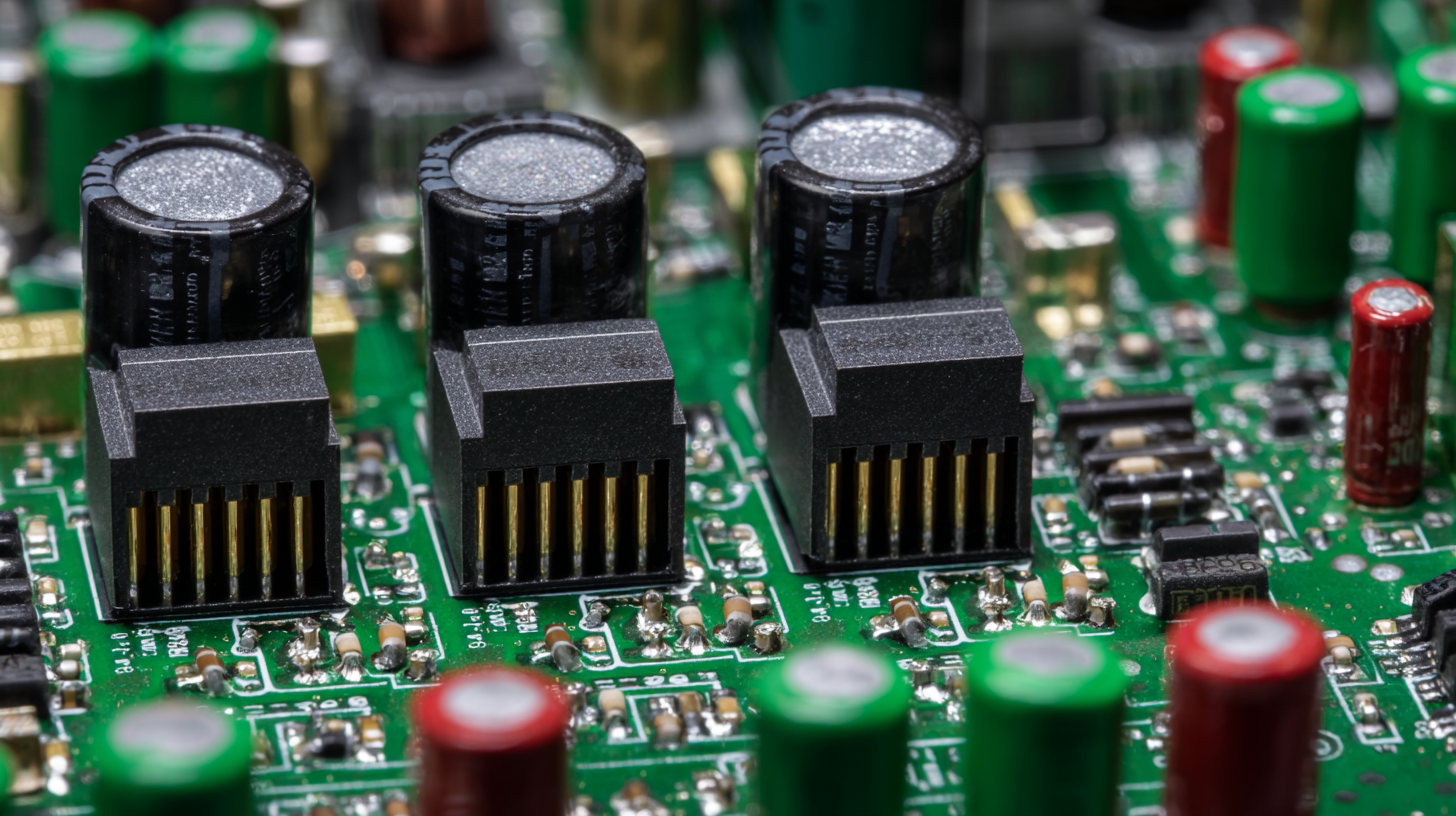

Selecting the right circuit board breaker is crucial for ensuring optimal performance and safety in electrical systems. Start by understanding the different types of circuit board breakers available in the market. According to a recent report by the International Electrotechnical Commission (IEC), demand for modular circuit breakers has surged by 15% annually, indicating a growing preference for versatility and efficiency in circuit protection. Evaluate whether you need a thermal, magnetic, or hydraulic-magnetic breaker based on your specific application and load requirements.

Tips: Always check the current rating and breaking capacity of the circuit board breaker. Industry standards suggest that breakers should be rated slightly above the normal operating load to avoid nuisance tripping, while ensuring they can handle potential overload situations.

Moreover, consider the environmental conditions where the breaker will be installed. The National Electrical Manufacturers Association (NEMA) highlights that choosing a breaker with the correct enclosure rating can prevent failures due to dust, moisture, or extreme temperatures. Selecting a product with a good thermal performance rating is essential for longevity and reliability.

Tips: Look for products with certifications from recognized organizations, as compliance with global standards can significantly reduce the risk of malfunction. Prioritize suppliers that provide transparent data on their products' performance under various conditions.

| Criteria | Description | Standard Rating (A) | Application |

|---|---|---|---|

| Overload Protection | Prevents circuit overloads that can damage components. | 15-50 | General electronics, small appliances |

| Short Circuit Protection | Provides immediate disconnection in case of a short circuit. | 10-100 | Industrial machinery, control systems |

| Thermal Stability | Maintains performance in varying temperature conditions. | 20-63 | Consumer electronics, HVAC systems |

| Voltage Rating | Ensures insulation can handle operational voltage. | 120-480 | Commercial installations, high voltage applications |

| Current Rating | Specifies the maximum continuous current allowed. | 5-250 | Data centers, telecommunications |

In the rapidly evolving world of electronics, circuit board manufacturers must navigate a complex landscape of compliance and certification requirements to ensure their products meet global industry standards. These standards not only enhance the quality and reliability of circuit board breakers but are also essential for gaining market access in various regions. Manufacturers are often required to comply with regulations set forth by organizations such as IEC (International Electrotechnical Commission) and UL (Underwriters Laboratories), which outline testing procedures and safety requirements for circuit board breakers.

Achieving compliance involves rigorous testing of circuit board breakers to verify they meet specified performance criteria. This includes evaluations for thermal, electrical, and mechanical characteristics under various operating conditions. Additionally, manufacturers must maintain thorough documentation to demonstrate adherence to these standards. Certification not only boosts the credibility of a manufacturer's products but also assures customers of their reliability and safety. As the industry continues to advance, staying updated on compliance and certification requirements will be essential for manufacturers seeking to thrive in a competitive global market.

As the technology surrounding circuit board breakers continues to evolve, it is crucial to stay informed about future trends and their implications for industry standards. One significant trend is the integration of smart technology into circuit board breakers, allowing for enhanced monitoring and control. These smart breakers are designed to communicate with other devices, providing real-time data on energy consumption and operational status, thus improving efficiency and enabling proactive maintenance.

Tip: When considering upgrades to circuit board breakers, focus on options that offer connectivity features, as they can significantly enhance the lifespan and performance of your electrical systems.

Another emerging trend is the development of more sustainable and energy-efficient breakers. Manufacturers are increasingly prioritizing eco-friendly materials and processes in their designs, aiming to reduce the environmental impact of circuit board breakers. These innovations not only align with global sustainability goals but also often lead to cost savings for businesses as energy-efficient products reduce long-term operating expenses.

Tip: Look for circuit board breakers that comply with the latest environmental standards, as these will not only help your organization stay compliant but also attract environmentally-conscious clients.