In today's advancing recycling industry, the demand for effective waste management solutions continues to rise, particularly for rubber tires, which constitute a significant portion of global waste. According to a report by the European Tyre and Rubber Manufacturers' Association, approximately 1.5 billion tires are discarded annually worldwide, leading to increased pressure on businesses to implement efficient recycling processes. A critical component in this endeavor is the selection of an appropriate Rubber Tire Shredder, which plays a vital role in converting waste tires into reusable materials. Choosing the right shredder can dramatically improve operational efficiency, reduce costs, and enhance product quality. This ultimate guide aims to assist business owners in navigating the complexities of selecting a Rubber Tire Shredder that aligns with their specific operational needs and sustainability goals.

When selecting a rubber tire shredder for your business, there are several key factors to consider that can significantly impact your efficiency and productivity. First and foremost, it’s essential to assess the shredder's capacity. Different models cater to various throughput requirements, so understanding your volume of tires processed daily will help in choosing a machine that meets your operational needs. Choose a shredder that not only matches your current output but also allows for future scaling as your business grows.

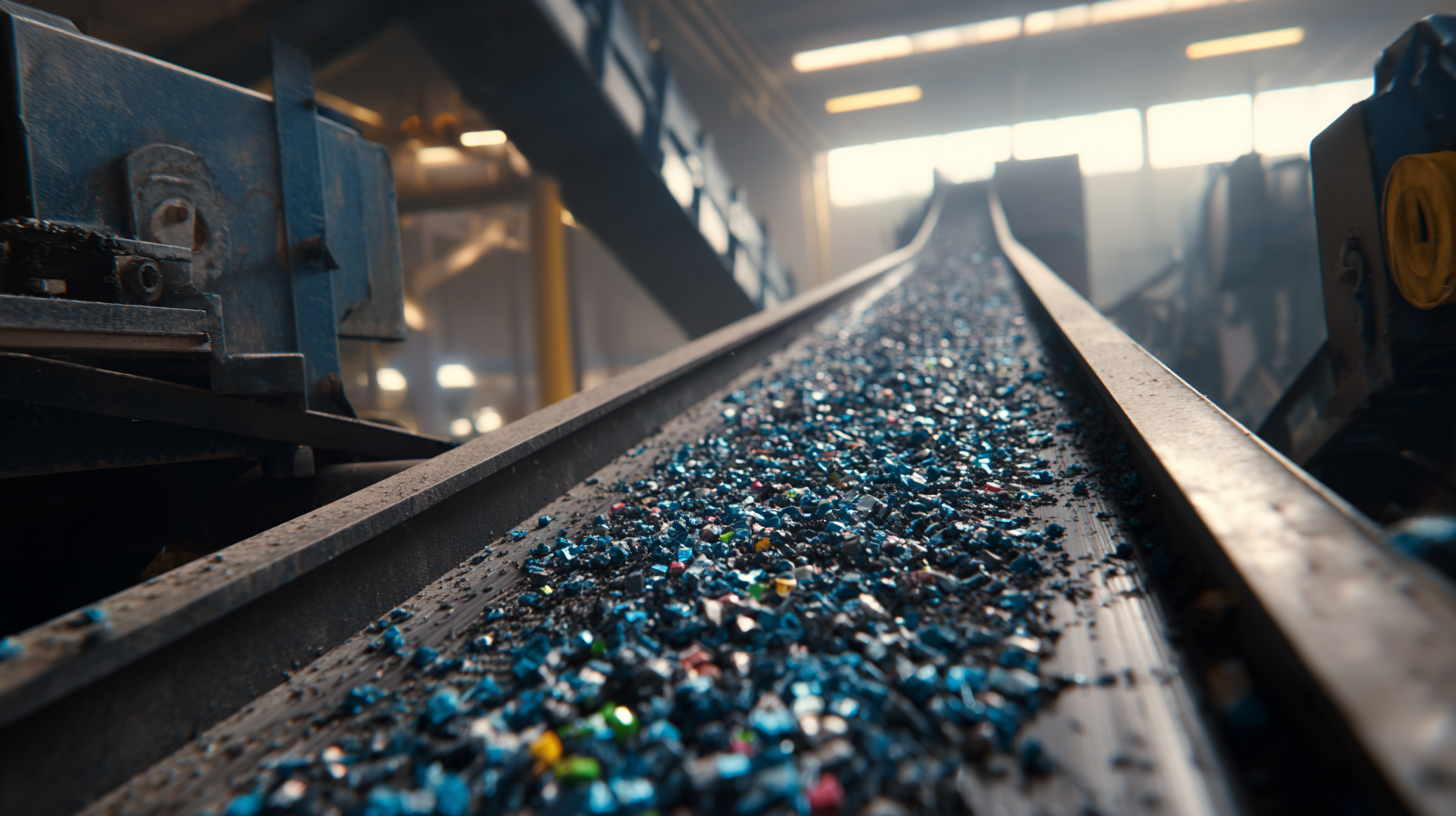

Another critical factor is the type of shredder technology employed. Some shredders utilize rotary or granulating systems, while others may incorporate higher-end technologies for finer granulation. Consider the end product you aim to achieve with the shredded tires—whether it’s for tire recycling, material production, or other applications—as this will inform your choice of technology. Additionally, evaluate the maintenance and operational costs, including energy consumption and wear-and-tear on parts, as these can influence your long-term profitability. A robust machine with lower maintenance needs can save you time and resources in the long run.

Another critical factor is the type of shredder technology employed. Some shredders utilize rotary or granulating systems, while others may incorporate higher-end technologies for finer granulation. Consider the end product you aim to achieve with the shredded tires—whether it’s for tire recycling, material production, or other applications—as this will inform your choice of technology. Additionally, evaluate the maintenance and operational costs, including energy consumption and wear-and-tear on parts, as these can influence your long-term profitability. A robust machine with lower maintenance needs can save you time and resources in the long run.

When considering a rubber tire shredder for your business needs, understanding the different types available is crucial. There are primarily three categories: portable shredders, inline shredders, and stationary shredders. Portable shredders are ideal for small operations or those requiring mobility and flexibility, whereas inline shredders are designed for integration into existing systems for continuous material processing. Stationary shredders, on the other hand, are best suited for large-scale operations and can handle higher volumes, maximizing efficiency and throughput.

According to a recent industry report by Technavio, the global tire recycling market is expected to grow by USD 1.26 billion between 2021 and 2025, primarily driven by the increasing adoption of tire recycling technologies. This surge emphasizes the importance of choosing the right shredder type not just for operational needs, but also for staying competitive in a rapidly evolving market.

**Tip:** When selecting a tire shredder, consider both the volume of tires you plan to process and the desired final product size. Each shredder type has specific capabilities tailored to different operational demands.

**Tip:** Conduct a return on investment (ROI) analysis before purchasing. A detailed assessment of your production costs versus the potential revenue from recycled materials can guide you toward the most cost-effective shredder option for your business.

When selecting a rubber tire shredder for your business, evaluating production capacity and efficiency is crucial. Production capacity refers to the volume of tires a shredder can process within a specific timeframe, which can significantly impact your operations. A machine with a higher capacity will allow you to meet demand more effectively and optimize workflow, reducing downtime and increasing profitability. It's essential to forecast your business needs accurately to choose a shredder that aligns with your operational goals.

Efficiency is another critical factor to consider. An efficient tire shredder not only maximizes output but also minimizes energy consumption and maintenance costs. Look for machines with advanced technology that streamlines the shredding process while maintaining high performance. Features like adjustable shredding sizes and automated feed mechanisms can enhance efficiency further. By prioritizing these elements in your assessment, you can ensure that your investment in a rubber tire shredder pays off in both productivity and sustainability for your business.

Investing in a rubber tire shredder can significantly enhance the efficiency of your business while promoting eco-friendly practices. When assessing the cost-effectiveness and ROI of these investments, it's crucial to consider both upfront expenses and long-term financial benefits. According to a report by the Recycling Association, tire shredding can reduce disposal costs by up to 50%, demonstrating immediate savings that can offset the initial purchase and operational costs of a shredder.

Additionally, the market for recycled tire products is on the rise, with the global rubber market projected to grow to $11.9 billion by 2025, as highlighted in the latest Market Research Future report. This creates a lucrative opportunity for businesses that utilize shredded tires, as they can further generate revenue by selling the processed material to various industries, including construction and automotive sectors. By carefully analyzing these factors, businesses can ensure that their tire shredder investment yields a favorable return and aligns with their broader financial goals.

When choosing a rubber tire shredder for your business, one of the most critical factors to consider is the maintenance and support provided by the manufacturer. A reliable shredder can significantly enhance your operations, but without proper upkeep, even the best equipment can suffer performance issues. Look for a manufacturer that offers comprehensive maintenance plans, including regular check-ups and easy access to spare parts. This ensures that downtime is minimized, allowing you to maintain productivity in your operations.

In addition to maintenance, consider the level of support available from the manufacturer. A strong customer service team can make a world of difference when you encounter issues or need assistance with your equipment. Opt for manufacturers that provide resources such as detailed manuals, troubleshooting guides, and responsive technical support. This combination of proactive maintenance and reliable customer service can lead to a smoother, more efficient operation, ultimately supporting your business's growth and longevity in the competitive recycling industry.

| Feature | Importance | Considerations | Examples |

|---|---|---|---|

| Durability | Essential for longevity | Material quality, construction type | High-grade steel, reinforced components |

| Maintenance Support | Affects uptime | Availability of parts, service response time | 24/7 support, local service centers |

| Efficiency | Directly impacts productivity | Shredder speed, power consumption | High RPM, energy-efficient models |

| Safety Features | Critical for operational safety | Emergency stops, guards | Operator training, compliance certifications |

| Technology Integration | Enhances operational control | Automation, monitoring systems | IoT capabilities, software compatibility |