As the demand for efficient recycling solutions grows, the role of our industry changes. Dr. Emily Carter, a leading expert in plastics processing, emphasizes, "Investing in the right HDPE shredder machine is crucial for effective waste management." This perspective highlights the importance of choosing innovative technology in this field.

In 2026, selecting the best HDPE shredder machine models will be more critical than ever. With the increasing focus on sustainability, companies must adapt. While many machines exist, distinguishing between models can be tedious and confusing. Efficiency and effectiveness become elusive goals without the right tools.

Attention to detail in selecting a shredder is vital. Many businesses overlook capacity, durability, and maintenance needs. Failing to consider these factors can lead to inefficiencies. The wrong choice might hinder recycling efforts, undermining the objective of reducing plastic waste. Recognizing these challenges is essential for making informed decisions in a rapidly evolving industry.

HDPE shredder machines play a crucial role in the recycling industry. These machines effectively reduce high-density polyethylene waste into manageable sizes. The recycling process becomes efficient when using advanced shredding technology. According to recent industry reports, the global market for plastic shredders is expected to grow by 4.5% annually through 2026. This growth emphasizes the importance of investing in reliable shredder models.

In 2026, the shift toward more eco-friendly practices continues. Shredder machines are becoming more energy-efficient, reducing operational costs. Some models claim to reduce energy consumption by up to 30%. However, challenges persist. Not all machines can handle various types of HDPE waste. This limitation can hinder processing efficiency. The right machine should match specific recycling needs for optimal results.

Additionally, maintenance remains a significant concern. Regular servicing can prolong the lifespan of shredders. Neglecting maintenance can lead to mechanical failures. Reports indicate that about 15% of downtime in recycling facilities is due to shredder maintenance issues. Awareness of these challenges is crucial for businesses. Investing in the right shredder can lead to improved recycling efficiency and waste reduction.

| Model | Shredding Capacity (kg/h) | Power (kW) | Weight (kg) | Features |

|---|---|---|---|---|

| Model A | 500 | 20 | 300 | High efficiency, low energy consumption |

| Model B | 750 | 30 | 350 | Compact design, easy maintenance |

| Model C | 1000 | 40 | 400 | Advanced control system, high throughput |

| Model D | 1200 | 50 | 450 | Versatile applications, user-friendly interface |

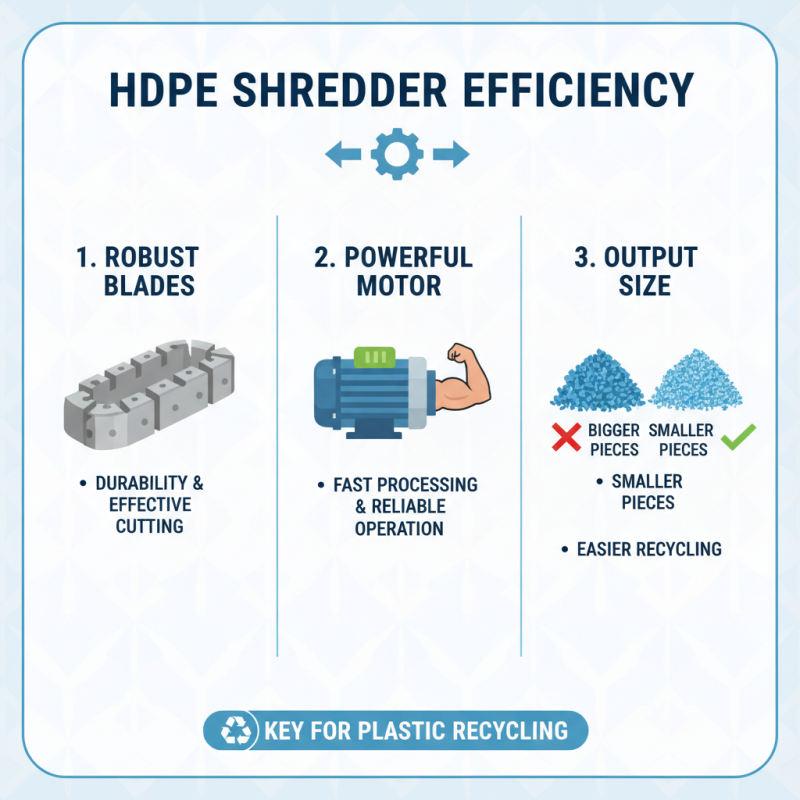

When selecting an HDPE shredder for 2026, consider key features that enhance efficiency. A reliable shredder must have a powerful motor. This allows it to handle diverse plastic waste effectively. Look for models with adjustable cutting sizes. This flexibility helps in achieving the desired granule size for recycling.

Another important aspect is the shredding capacity. Machines with higher capacities save time and energy. A shredder with robust safety features is crucial. This ensures safe operation, minimizing the risk of accidents during use.

Ease of maintenance cannot be overlooked. Shredders that are easy to clean and service require less downtime. Additionally, advanced noise reduction technologies are beneficial. They create a more pleasant working environment. However, not every feature may be necessary for your specific needs. Reflect on what fits your recycling process best. Balancing efficiency and practicality will lead to better outcomes in recycling operations.

When searching for effective HDPE shredders for 2026, it's essential to explore leading brands. Many manufacturers offer innovative technology. This technology enhances the shredding process, making it more efficient. Key aspects include durability, performance, and ease of use.

Some brands focus heavily on energy efficiency. Users expect machines that not only perform well but also save on energy costs. This need can lead to challenges, as not all models achieve this balance. Additionally, maintenance requirements can vary significantly among different models, impacting overall usability.

Look for brands that prioritize customer support. A trustworthy brand should provide reliable service options. Be aware that choosing the wrong brand can lead to wasteful expenses. Many users overlook this aspect and regret it later. Researching reviews and specifications is crucial for informed decisions. This approach ensures both performance and longevity in your shredding operations.

This chart illustrates the shredding capacities of various HDPE shredder machine models projected for 2026. The data reflects the expected performance based on current models available in the market.

When considering HDPE shredders, efficiency is key. Understanding how different models perform can guide your decision. Several features impact performance. Look for shredders with robust blades and powerful motors. These elements are crucial for effective recycling. The size of the output material also matters. Smaller pieces are easier to process later.

Deeper analysis reveals that not all shredders are created equal. Variations in design can lead to significant differences in output quality. Certain models may struggle with thicker materials. This can create bottlenecks in the recycling process. Additionally, energy consumption is an important factor. Some shredders use more energy than necessary. This raises operational costs over time.

It’s important to consider user feedback too. Some models might underperform, despite claims of high efficiency. Look for real-world reviews and data. They often highlight issues like clogging and maintenance needs. The design might seem appealing, but practicality varies. Examine warranty and support options as well. A reliable service can make a significant difference in long-term performance.

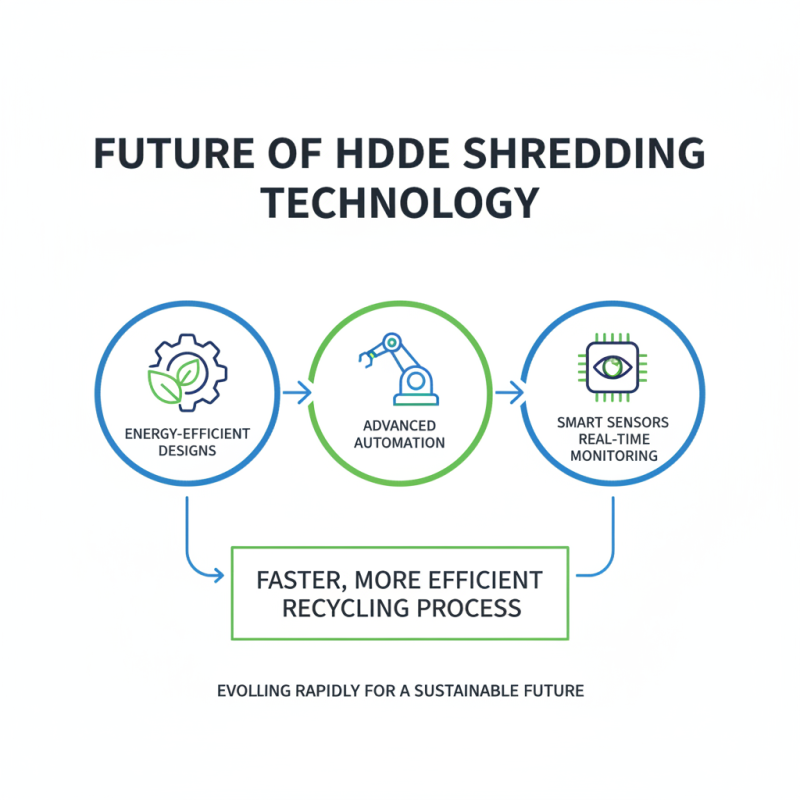

The future of HDPE shredding technology is evolving rapidly. Trends indicate a shift towards more energy-efficient designs. Advanced automation is becoming crucial in many models. With these advancements, the recycling process can be both faster and more efficient. Newer models will feature smart sensors. These sensors can monitor performance in real time.

Greater customization options are emerging for HDPE shredders. This allows for adaptability to different types of materials. Companies can specify settings based on their needs. This level of customization enhances operational efficiency. However, this evolution does come with challenges. As technology advances, so do maintenance needs. It can be hard to keep up with new systems and their requirements.

Tips for choosing a shredder include considering energy use. Efficient models save both cost and environmental impact. Always assess the shredder's capacity. Find models that suit your recycling volume. Regularly review new technologies. Staying informed helps avoid outdated processes. Investing in training for your team can enhance efficiency too.