In recent years, the emergence of the "Pla Shredder" has revolutionized waste management. Leading industry expert, Dr. Emma Collins, notes, "The Pla Shredder not only reduces size but also enhances recycling efficiency." This innovative machine breaks down polylactic acid (PLA) materials, enabling easier processing and repurposing.

Moreover, Pla Shredders have become essential in industries focusing on sustainability. They cater to businesses aiming to minimize their environmental impact. Despite their advantages, some users may overlook the importance of proper maintenance. Neglecting this can lead to reduced performance and increased costs.

As recycling technologies evolve, the Pla Shredder stands out. It presents both opportunities and challenges. While it promises a greener future, it also demands careful consideration and commitment. The balance of practicality and eco-friendliness is vital in leveraging this technology effectively.

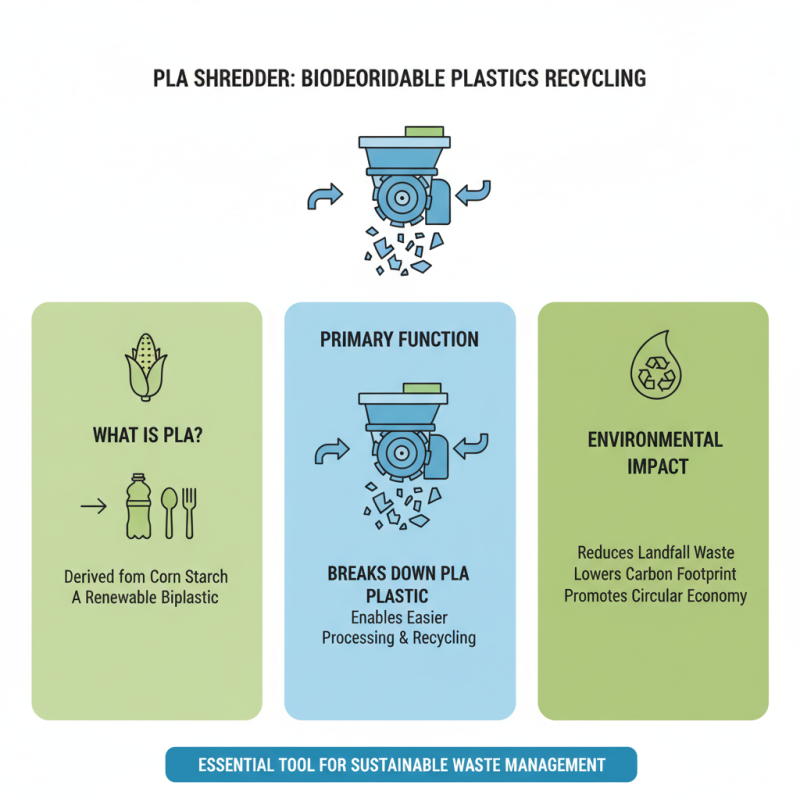

A PLA shredder is an innovative tool designed to process polylactic acid (PLA) materials. PLA is a biodegradable plastic derived from renewable resources, like corn starch or sugarcane. As the world shifts towards sustainable alternatives, the need to recycle and repurpose PLA is becoming crucial. A PLA shredder helps in breaking down used PLA products, making them easier to recycle or repurpose.

Typically, a PLA shredder operates with sharp blades that cut the material into small pieces. This process increases the surface area, allowing for more efficient chemical or thermal recycling options. The machine is built to handle various forms of PLA, from cups to packaging. However, the efficiency of these machines can vary. Sometimes, they may struggle with thicker or more rigid PLA items. Moreover, proper maintenance is essential. A neglected shredder can lead to performance issues and increased downtime.

Using a PLA shredder can significantly contribute to waste reduction. However, the process isn't flawless. Operators must keep an eye on energy consumption and potential wear on the blades. It's important to reflect on the overall impact of such machines. Are we truly recycling effectively? Or could we do better with our practices? Evaluating these questions is key to improving our approach to sustainability.

A PLA shredder is an essential tool in waste management focused on biodegradable polymers. Its primary purpose is to break down PLA plastic, a renewable material derived from corn starch. By shredding, it enables easier processing and recycling. This step is crucial in reducing the environmental impact of plastic waste.

Using a PLA shredder has significant benefits. It helps convert bulky PLA products into smaller pieces. These smaller shreds are easier to handle and transport. They can be integrated into different recycling processes. Additionally, shredding enhances the efficiency of composting. Smaller materials decompose faster, enriching the soil more effectively.

However, some challenges exist. Not all PLA items are suitable for shredding. Contaminants can hinder the recycling process. Careful sorting is necessary to ensure efficiency. The machine itself requires regular maintenance, which can be a hassle. A shredder may not solve the entire problem, but it is a step towards a sustainable future.

A PLA shredder is an essential tool in waste management, especially for biodegradable materials. It breaks down polylactic acid (PLA), a common bioplastic derived from renewable resources. The machine operates by using sharp blades to slice PLA items into smaller pieces. This process makes recycling or composting more effective.

Efficiency is key. Studies show that shredding can increase the surface area of materials, aiding in decomposition. By reducing PLA waste into smaller fragments, the breakdown time in composting facilities can decrease significantly. According to the Biodegradable Products Institute, shredded PLA can decompose up to 30% faster in proper conditions compared to unshredded items.

However, it's not always perfect. Some PLA shredders struggle with consistency in the particle size. This inconsistency can lead to issues during the composting process. Additionally, there are concerns about contamination in the recycling stream. Improperly sorted materials can hinder the effectiveness of recycling programs. Addressing these challenges is crucial for improving investment in PLA shredder technology and waste management strategies.

| Dimension | Description | Material Type | Typical Output Size | Applications |

|---|---|---|---|---|

| Power Consumption | Energy used during operation | PLA | 1-5 mm | Recycling and waste management |

| Shredding Speed | Speed at which material is shredded | PLA | Variable | Plastic recycling |

| Maintenance Requirements | Frequency of required maintenance | PLA | N/A | Industrial applications |

| Noise Level | Decibel level during operation | PLA | Moderate | Waste processing |

| Safety Features | In-built safety mechanisms | PLA | N/A | Public and employee safety |

When selecting a PLA shredder, consider its key features carefully. A powerful motor is essential. It ensures efficient shredding of PLA materials without overheating. Look for models with various speed settings. This flexibility allows you to adjust according to the material thickness. Some shredders have hardened blades. These blades provide durability and can handle tough jobs.

Size matters too. A compact shredder can fit small workspaces. However, larger models may offer better functionality. Noise levels are another consideration. Some shredders operate quietly, which is beneficial in shared environments. Also, check the safety features. Auto-stop mechanisms prevent accidents, especially in busy workshops.

Pay attention to user reviews. They often reveal real-world issues that specifications might not show. Users sometimes find certain features less effective than advertised. It’s important to understand the real capabilities of the shredder. Research can help avoid disappointing purchases. Balancing price and quality is also a challenge. Sometimes, spending a bit more can lead to better satisfaction in the long run.

PLA shredders play a crucial role in various industries. They are primarily used to process polylactic acid (PLA) materials. PLA is biodegradable and derived from renewable resources. This characteristic makes it popular in packaging, textiles, and 3D printing. However, managing PLA waste can be challenging without proper shredding techniques.

In the packaging industry, PLA shredders effectively recycle old PLA products. They convert them into smaller pieces for efficient reuse. This process not only reduces waste but also lowers production costs. In textile manufacturing, shredders help create recycled fibers from PLA fabrics. This shift supports sustainability in fashion, which often struggles with waste issues.

However, while these machines are beneficial, they are not perfect. Maintenance is crucial to ensure longevity and efficiency. Operators must regularly check for wear and tear. Sometimes, the shredded material may not meet quality standards. Continuous improvement in shredder technology is necessary. Achieving optimal performance remains a work in progress.