In the ever-evolving landscape of waste management, finding effective solutions is critical. One expert in the field, Dr. Emily Larson, a leading voice in sustainable technology, emphasizes, “The Plastic Head Shredder is not just a machine; it's a catalyst for change.” This underscores the growing significance of the Plastic Head Shredder in addressing waste efficiently.

Utilizing the Plastic Head Shredder can profoundly impact recycling processes. It transforms plastic waste into manageable pieces, paving the way for easier recycling. The machine employs sharp blades designed to handle various types of plastics. These include those typically challenging to process. However, not all models offer optimal performance.

Moreover, users may struggle with maintenance issues or blade replacements. These challenges invite reflection and adjustment. While the Plastic Head Shredder presents notable advantages, operators must adapt to maximize its potential. The journey towards efficient waste management is ongoing, and each step shows promise yet demands careful consideration.

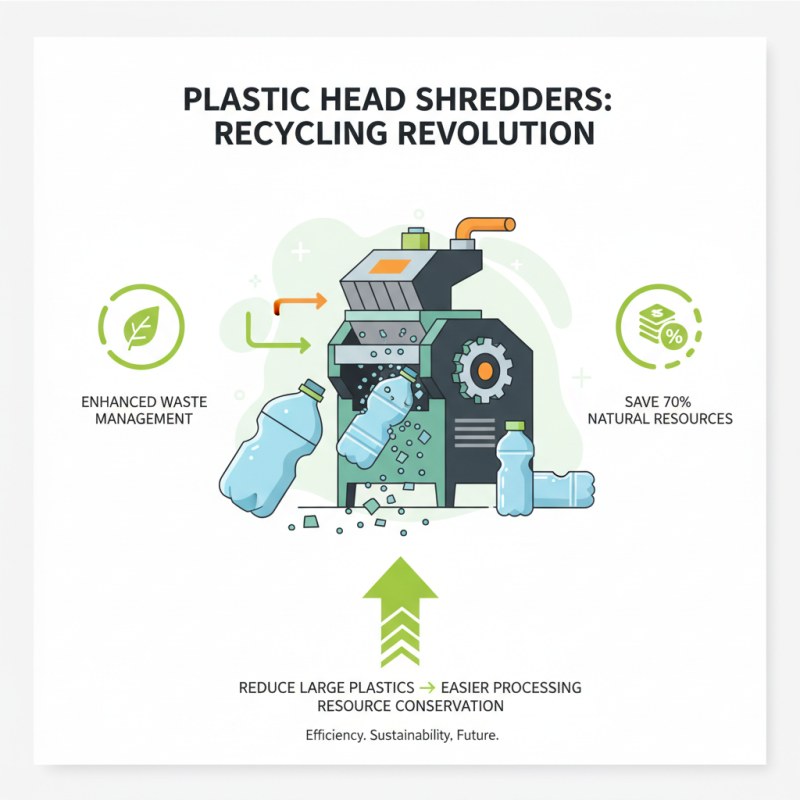

Plastic head shredders are essential for modern waste management. They reduce plastic waste volume efficiently. When plastics are shredded, transport and disposal become simpler. This process minimizes the environmental footprint of waste. Shredders turn bulk plastic into manageable sizes, addressing space issues in landfills.

One significant benefit is that shredded plastic can be recycled more easily. Smaller pieces allow for better melting and reforming into new products. This creates a closed-loop system, reducing reliance on new materials. Furthermore, shredding helps in sorting mixed plastics, which often complicates recycling efforts. The challenge remains: not all plastics can be recycled readily.

Consider the noise and energy consumption of these machines. While they are effective, they also require maintenance and proper handling. Users must ensure they are used correctly to maximize efficiency. An improper operation can lead to increased waste or even damages. Finding the right balance in usage is crucial for achieving optimal results.

Plastic head shredders play a vital role in recycling processes. They significantly enhance waste management efficiency. Research shows that plastic waste recycling can save up to 70% of natural resource consumption. These machines effectively reduce large plastic items into manageable pieces. This breakdown makes it easier for recycling facilities to process materials.

Furthermore, plastic head shredders can increase the quality of the recycled output. Fine shredding improves material consistency. Studies indicate that uniform particle sizes lead to a 30% enhancement in recycling yields. Diversified plastic types can be processed without extensive sorting. However, operators must be aware of maintenance requirements. Regular checks are vital to avoid downtime.

Not all shredders perform equally. Some may struggle with tougher plastics. This inconsistency can hinder the recycling rate. Operators should reflect on their equipment choices regularly. They must ensure that their shredders meet evolving industry standards. Efficient waste management relies heavily on effective shredding solutions.

When selecting a plastic head shredder, it’s essential to focus on key features that enhance efficiency. A robust shredding capacity is vital. Studies reveal that shredders with a capacity of 500 kg/hr can significantly improve waste management operations. This capacity allows organizations to process large volumes of plastic quickly. Faster processing reduces the backlog of waste.

Another crucial feature is the blade design. High-quality, durable blades can handle various plastic types without jamming. In fact, innovative blade technologies can improve shredding efficiency by nearly 30%. They ensure consistent particle size, making further recycling easier. However, blades do wear out over time. Regular maintenance is necessary to sustain performance.

Consider noise levels too. Many industrial shredders operate at high decibels, exceeding recommended limits. Choosing a quieter model can enhance workplace safety. Moreover, operational durability matters. A shredder designed for heavy use can prevent frequent breakdowns. This is vital for maintaining productivity and reducing downtime. While these features are important, not all shredders provide the perfect balance. Users should evaluate their specific needs to find the most suitable option.

| Feature | Description | Importance |

|---|---|---|

| Cutting Efficiency | High-speed blades for effective shredding of plastic. | Crucial for reducing processing time and improving throughput. |

| Durability | Robust construction for long-term operation. | Ensures reliability and reduces maintenance costs. |

| Safety Features | Emergency stop, guards, and safety sensors. | Protects operators and complies with safety regulations. |

| Energy Efficiency | Low power consumption during operation. | Reduces operational costs and environmental impact. |

| Versatility | Ability to shred various types of plastic materials. | Enhances adaptability for different waste management needs. |

The environmental impact of plastic head shredders is becoming increasingly significant. These machines play a crucial role in waste management by converting plastic waste into smaller, manageable pieces. According to a report by the Environmental Protection Agency (EPA), more than 35 million tons of plastic waste ends up in landfills each year. Shredders help reduce this volume.

One advantage of plastic shredding is the potential for recycling. Shredded plastic can be repurposed into new products. This process helps conserve petroleum resources and reduces greenhouse gas emissions. Additionally, a study from the Plastic Pollution Coalition indicates that recycling plastic can save up to 70% of the energy compared to producing new plastic.

Tips: Always choose high-quality shredders. They should be durable and efficient. Regular maintenance is crucial for optimal performance. Assess your waste volume to determine the appropriate shredder size.

However, not all shredders are equal. Some may struggle with tougher plastic types. It’s essential to research and understand the specifications. Using a less suitable shredder could lead to ineffective waste processing. Ultimately, selecting the right equipment makes a difference in waste management outcomes.

Plastic head shredders have become a game-changer in waste management. They offer unique benefits when compared to traditional shredders. Data shows that plastic head shredders can process materials more efficiently. For instance, they can reduce plastic waste volume by up to 80%. This means less space is needed for storage and transport.

Traditional shredders often fail to handle mixed materials effectively. They struggle with plastics, metals, and non-recyclables. This can lead to increased downtime and maintenance costs. In contrast, plastic head shredders feature specific designs tailored for better performance. Reports indicate that they require up to 30% less energy to operate, proving to be more environmentally friendly.

Adopting plastic head shredders can be a challenge for some. They may not be compatible with existing waste systems. Training staff on new equipment takes time and resources. Therefore, organizations need to evaluate their operations before making a switch. While the benefits are clear, the transition requires thoughtful consideration to avoid pitfalls.