In the modern recycling landscape, the "Rubber Tire Shredder" plays a vital role. These machines assist in transforming discarded tires into usable materials. Mike Thompson, an industry expert, once stated, "Rubber Tire Shredders are crucial for turning waste into opportunity." This highlights the importance of progress in tire recycling.

The technology behind Rubber Tire Shredders is fascinating. They cut tires into small pieces, making material handling easier. However, not all shredders are built the same. Some may lack efficiency and performance. It’s essential to choose equipment that meets industry standards. A poorly functioning shredder can lead to increased costs and environmental impact.

Despite the benefits, challenges remain. Many facilities do not leverage the full potential of their Rubber Tire Shredders. Operators may struggle with maintenance or overlooking safety protocols. Addressing these issues is vital for maximizing productivity. Reflection on these practices is necessary for improvement. Ultimately, the journey of tire recycling relies heavily on the effectiveness of Rubber Tire Shredders.

Rubber tire shredders are machines designed to break down used tires into manageable pieces. Their primary purpose is to facilitate recycling. Shredding tires makes it easier to repurpose the rubber for various applications. This process helps reduce waste and promotes environmental sustainability.

The size of the shredded material varies, depending on the settings of the machine. Typically, this can range from small granules to larger chips. Effective shredding requires careful control of the blade configuration and speed. Poor calibration may lead to unevenly sized pieces, creating challenges for downstream processing.

Additionally, these machines can sometimes face operational issues. Overheating can become a concern, and maintaining the blades is vital for durability. Regular inspections are essential to ensure optimal performance. Users must reflect on these factors to maximize efficiency and enhance the recycling process. Striving for consistent output remains a common challenge in the industry.

| Feature | Description |

|---|---|

| Definition | A machine designed to shred used tires into smaller pieces for recycling or disposal. |

| Main Purpose | To reduce tire volume and facilitate the recycling process. |

| Common Applications | Rubber material for playgrounds, sports surfaces, or fuel. |

| Types of Shredders | Primary shredders, secondary granulators, and specialized tire shredders. |

| Shredding Process | Involves feeding tires into the machine where they are cut into small pieces using rotating knives. |

| Benefits | Reduces landfill waste, conserves resources, and produces reusable material. |

| Environmental Impact | Helps in reducing pollution and promotes sustainable waste management. |

A rubber tire shredder is essential for recycling. It breaks down tires into smaller pieces. This process aids in environmental sustainability. The efficiency of shredders can impact overall recycling rates.

Key components of a rubber tire shredder include the hopper, knives, and screens. The hopper feeds tires into the machine. It must be robust to handle heavy loads. Knives are the heart of the shredder. They need to be sharp and durable. According to industry reports, proper knife maintenance can enhance shredding performance by up to 20%.

Screens dictate the size of the shredded material. They ensure uniformity in particle size. This directly influences the recycling process. Despite the technology used, some challenges remain. For instance, achieving consistent sizing of shreds is often difficult. This can impact subsequent processing steps. Continuous innovation in design can improve these components’ effectiveness and efficiency.

The tire shredding process begins with the collection of used tires. These tires are often stacked in piles, waiting for recycling. It's estimated that around 1 billion tires are discarded each year worldwide. This presents an urgent need for effective recycling methods.

Once collected, tires are fed into a rubber tire shredder. The shredder uses powerful blades to cut the tires into smaller pieces. Typically, the size of the output is around 2 to 6 inches. This process is crucial since it facilitates the further recycling of rubber, steel, and fiber. Data suggests that shredding can increase the value of the materials recovered, helping to divert over 70% of tires from landfills.

After shredding, the rubber pieces undergo additional processes. These may include granulation or crumb rubber production. However, the operations aren’t without challenges. Variations in tire composition can affect the shredding efficiency and output quality. This inconsistency often leads to a mix of materials that requires further sorting. Adjustments in the process become essential for optimal results. Each step matters in maximizing material recovery for a sustainable future.

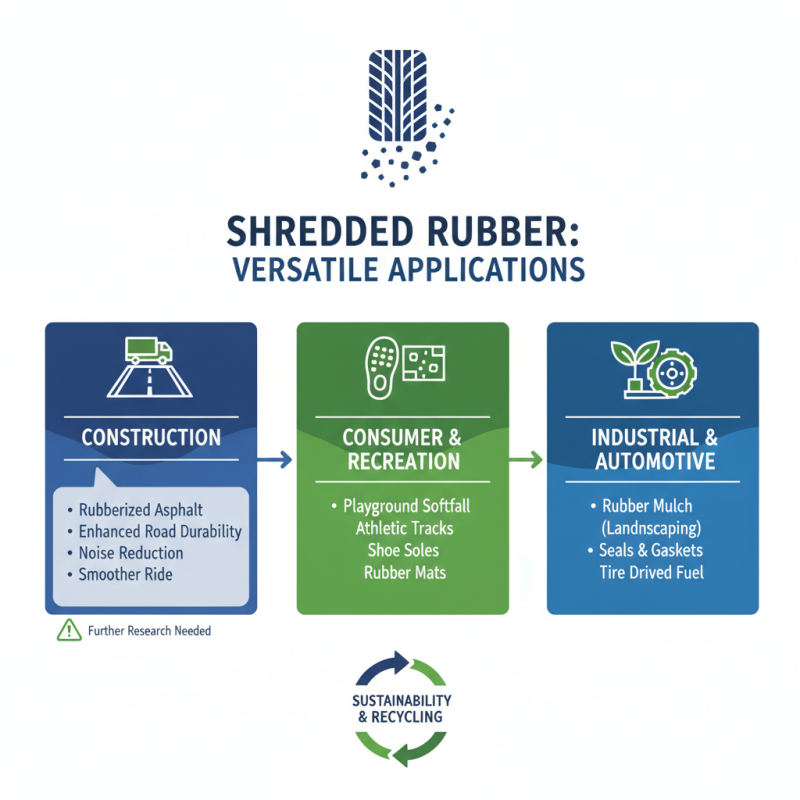

Shredded rubber finds diverse applications across many industries, showcasing its versatility. In construction, it is used in rubberized asphalt. This mixture enhances road durability and reduces noise. It creates a smoother ride, but it still needs more research for widespread implementation.

The landscaping industry benefits from shredded rubber as well. It is used as mulch, providing a weed barrier and retaining moisture in gardens. This eco-friendly option prevents soil erosion, though some worry about rubber leaching into soil. There are concerns that long-term exposure might affect plant growth.

Moreover, shredded rubber plays a critical role in sports facilities. It is an integral part of safety surfacing for playgrounds and tracks. The cushioning effect minimizes injuries, but not all facilities ensure consistent material quality. Inconsistent rubber grades can lead to safety issues over time, highlighting a need for better standards in production and usage.

Rubber tire shredders play a vital role in recycling old tires. These machines break tires into smaller pieces, making further processing easier. The shredded rubber can be reused in various applications, such as paving, flooring, and insulation. This process reduces waste and helps conserve resources.

Using rubber tire shredders offers several advantages for recycling. First, it minimizes landfill waste. Millions of tires are discarded every year. Shredding them decreases the volume significantly. Additionally, shredded rubber has market value. It can be sold to manufacturers, providing an economic incentive for recyclers. This creates jobs and supports local economies.

However, not all tire recycling operations are perfect. Some facilities struggle with improper sorting of materials. Contaminants mixed with tires can cause issues during shredding. This affects the quality of shredded rubber. There’s also the challenge of ensuring the equipment is maintained properly. Broken machines lead to downtime and waste, which can be frustrating. So, continuous improvement is necessary for more efficient recycling processes.