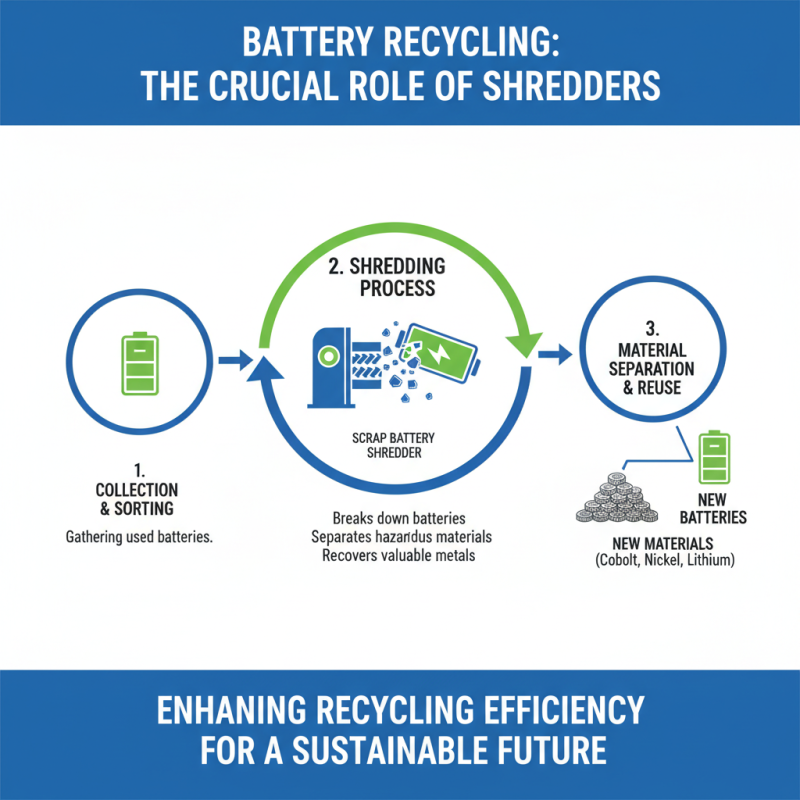

In the realm of recycling, the efficiency of a Scrap Battery Shredder is crucial. Industry expert Dr. Mark Johnson states, "A Scrap Battery Shredder can significantly enhance material recovery rates." This tool stands at the forefront of battery recycling technology, breaking down battery components into manageable sizes.

With the growing concern over battery waste, the demand for effective solutions increases. Scrap Battery Shredders play a vital role in ensuring hazardous materials are processed safely. They minimize the environmental impact and pave the way for sustainable recycling practices.

Yet, there are challenges. Not every facility has access to advanced shredding technology. Many still rely on outdated methods, leading to inefficiencies. As the recycling landscape evolves, investment in innovative shredding technologies becomes essential. Embracing the Scrap Battery Shredder could define the future of effective recycling.

Scrap battery shredders play a vital role in recycling efforts. They efficiently process old batteries, breaking them down into smaller components. This step is crucial for recovering valuable materials like lead, lithium, and cobalt. Many recycling facilities have adopted these machines to streamline operations.

Understanding how these shredders work is essential. They use powerful blades to shred batteries into pieces. The size reduction allows for easier separation of metal and plastic parts. However, operating these machines comes with challenges. Battery components can be hazardous. Proper safety measures are necessary to avoid accidents.

Even with advanced technology, some issues persist. Not all materials are recovered perfectly. Some valuable content may still end up as waste. Facilities must regularly evaluate their processes. Ongoing improvements can enhance efficiency and recovery rates. Addressing these concerns is important for optimizing battery recycling.

Battery recycling is crucial. A scrap battery shredder plays a significant role in this process. Shredders break down batteries into manageable pieces. This step helps separate hazardous materials from valuable metals. It enhances overall recycling efficiency.

Using shredders also improves safety. Manual handling of batteries can pose risks. Shredders minimize human contact, reducing accidents. However, operators must ensure proper training. Misuse can lead to serious issues.

Increased material recovery is another advantage. Shredding enables better separation of components. This leads to higher yields of reusable materials. Yet, not all shredding processes are perfect. Some finer materials may be lost during shredding. Being mindful of these challenges is important for effective recycling.

Effective battery recycling plays a crucial role in reducing environmental harm. When batteries end up in landfills, they leach toxic materials. These substances can contaminate soil and groundwater, posing serious health risks. Recycling helps recover valuable metals. This reduces the need for mining new materials, which can be destructive to ecosystems.

Using a scrap battery shredder enhances the recycling process. It efficiently breaks down batteries into manageable pieces. This makes it easier to separate components for reuse. The technology helps minimize human error in handling hazardous materials. Yet, we still face challenges. Not all battery types are easily recyclable. Some recycling plants may lack proper facilities. These gaps can hinder effective recycling efforts.

Communities need to understand the importance of battery recycling. Awareness can spark initiatives to improve recycling practices. More education is needed to encourage responsible disposal. Individuals must recognize their role in this process. Small actions can lead to meaningful change. We must reflect on our consumption patterns and make better choices for the planet.

When considering a scrap battery shredder, several key features significantly enhance its effectiveness. One crucial aspect is the shredding capacity. A machine that can process a high volume of batteries ensures efficiency in recycling operations. According to industry reports, increasing shredding capacity can improve recycling rates by up to 30%. Such a boost is essential as the demand for recycled materials continues to rise.

Noise reduction features also matter. Battery shredders often operate in environments where noise pollution is a concern. Machines designed with advanced sound-proofing technology can minimize disruption. This feature is not just about compliance; it directly impacts worker comfort and productivity. Additionally, safety features like automatic shut-off and emergency stops are vital. An estimated 25% of workplace accidents in recycling facilities relate to machine malfunction.

Durability is another key factor. The harsh nature of recycling operations demands tools that can withstand heavy use. Analysis shows that shredders built with high-grade materials last longer and require fewer repairs. Cost efficiency in maintenance helps businesses avoid unexpected downtimes. Reflecting on these features is crucial. Decision-makers must thoroughly evaluate their needs and understand potential pitfalls in performance. Considerations often go beyond initial investment.

| Feature | Description | Importance |

|---|---|---|

| High Throughput | The ability to process large volumes of batteries efficiently. | Increases productivity and reduces processing time. |

| Safety Features | Includes mechanisms to prevent fires, explosions, and exposure to hazardous materials. | Protects operators and the environment. |

| Durability | Constructed with robust materials to withstand heavy usage. | Ensures long-term operation and reduces maintenance costs. |

| Versatility | Capable of shredding different types of batteries including lithium-ion, lead-acid, etc. | Allows for broader recycling opportunities and improved resource recovery. |

| Ease of Use | User-friendly controls and maintenance access for operators. | Reduces training time and operational errors. |

Operating a scrap battery shredder effectively requires a thoughtful approach. Safety is paramount. Always wear appropriate protective gear. This includes gloves, goggles, and masks. It's essential to ensure proper ventilation in the workspace. Shredding batteries can release harmful particles. Neglecting safety can lead to serious health risks.

Regular maintenance of the shredder is crucial. Check the blades frequently for signs of wear. Dull blades can cause inefficient shredding and may create hazardous situations. Adjusting the machine settings for different battery types can improve efficiency. Some materials may require specific considerations. Awareness of these factors is necessary for optimal performance.

Monitoring the shredding process is critical. Look for unusual noises or vibrations. These may indicate problems. Make adjustments as needed to avoid breakdowns. Documenting the process can provide valuable insights. Reflection on past operations can lead to improvements. Learning from mistakes is part of effective management.