In the modern era of environmental consciousness, efficient recycling has become a pivotal element of sustainable practices. One of the key technologies driving this initiative is the Plastic Shredder Machine. These machines play a crucial role in breaking down used plastic materials into manageable sizes, making them suitable for recycling processes. As plastic waste continues to accumulate globally, the demand for effective shredding solutions has surged, highlighting the importance of understanding the various types of plastic shredders available on the market.

This article delves into the top 10 Plastic Shredder Machines that everyone involved in recycling should be aware of. Each machine offers unique features and capabilities tailored for specific recycling needs, making it essential for businesses and individuals to choose wisely. By exploring these shredders, we aim to provide insight into their functionality, efficiency, and the impact they can have on enhancing recycling efforts. With the right Plastic Shredder Machine, we can significantly reduce plastic waste and contribute to a more sustainable future.

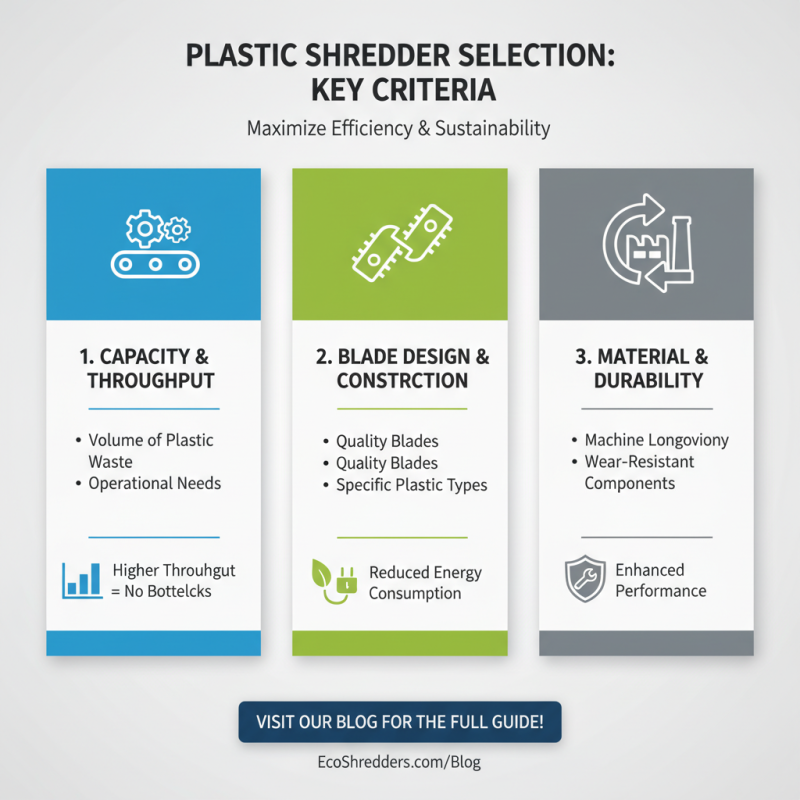

When selecting a plastic shredder machine for efficient recycling, understanding the key criteria is essential for maximizing performance and sustainability. One of the foremost factors is the machine's capacity and throughput. Depending on the volume of plastic waste you will process, a higher throughput machine may be necessary to meet your operational needs without bottlenecking the recycling process. Additionally, the machine's blade design and construction significantly impact shredding efficiency. Quality blades designed for specific types of plastics can reduce energy consumption and enhance overall shredding performance.

Another crucial aspect to consider is the machine's safety features and ease of maintenance. Since plastic shredders are often used in industrial settings, incorporating safety mechanisms, such as emergency stop buttons and protective shields, is vital to ensure operator safety. Regular maintenance accessibility is also important, as easy-to-replace parts and straightforward cleaning procedures can extend the machine's lifespan and ensure consistent operation. Lastly, energy consumption ratings should not be overlooked, as selecting an energy-efficient model can lead to considerable cost savings and a reduced environmental footprint.

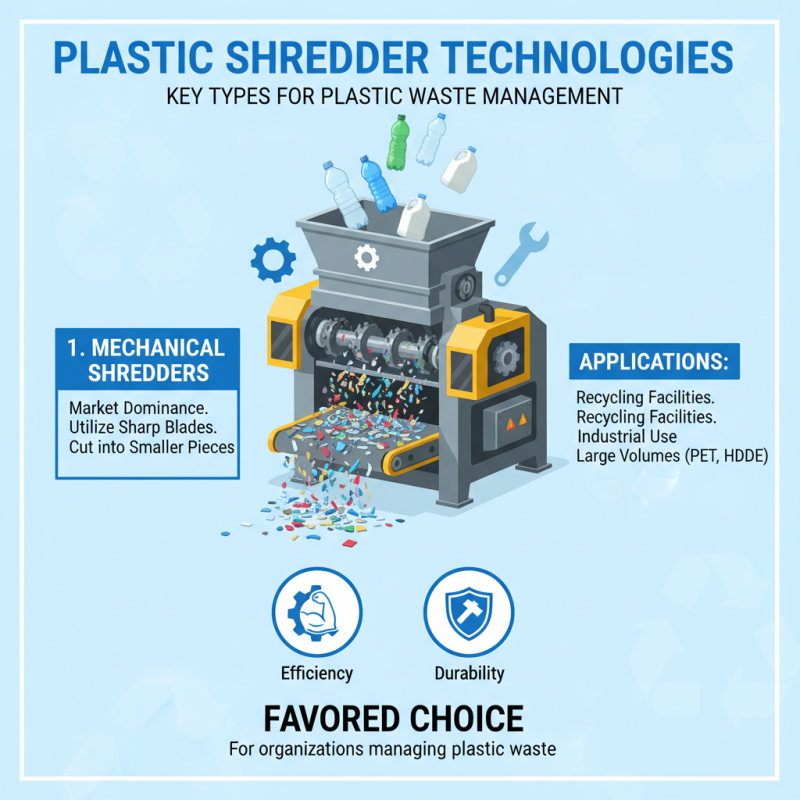

When exploring the world of plastic shredder technologies, it’s essential to understand the different types available today. Mechanical shredders dominate the market, utilizing sharp blades to cut plastic waste into smaller pieces. These machines are typically employed in recycling facilities and industrial applications, where large volumes of plastics, such as PET and HDPE, are processed. Their efficiency and durability make them a favored choice for organizations looking to manage plastic waste.

Another significant category is the granulator, which, while similar to mechanical shredders, takes the process a step further by granulating the shredded plastic into even finer particles. This method is particularly useful for achieving uniform sizes, which can enhance the quality of the recycled material. Additionally, there are specialized shredders designed for specific plastic types, such as electronic waste shredders that handle hard plastics and mixed materials. Understanding these distinct technologies can help organizations choose the right equipment tailored to their specific recycling needs, ultimately contributing to more effective plastic waste management.

The plastic recycling industry is on a robust growth trajectory, with the global market size projected to reach $755.9 billion by 2025, up from $709.8 billion in 2024. This steady expansion reflects a growing awareness of environmental sustainability and a rising demand for recycled materials across various sectors. The increased implementation of environmental regulations and initiatives aimed at reducing plastic waste are further fueling this upward trend.

Additionally, the recycled plastic market is anticipated to grow at a compound annual growth rate (CAGR) exceeding 8% from 2025 to 2034. Key drivers of this growth include consumer demand for sustainable packaging solutions and initiatives by industries to incorporate recycled materials into their products. With projections indicating a significant rise in the consumption of recycled plastics in packaging, automotive, and construction applications, the focus on efficient recycling processes, including advancements in plastic shredder technologies, will play a crucial role in meeting upcoming market demands.

When selecting a plastic shredder machine for efficient recycling, key features and specifications play a crucial role in enhancing shredding performance. A powerful motor is essential, as it influences how quickly and effectively the shredder can process various types of plastics. Look for machines equipped with high-torque motors that can handle tougher materials without hesitation. Additionally, the cutting mechanism should be robust and designed to minimize downtime; double-shaft or multi-blade systems often provide superior results in terms of uniform particle size and reduced noise levels.

Tips to maximize performance include regularly checking the blades for sharpness and wear. Dull blades can significantly reduce shredding efficiency and increase energy consumption. Furthermore, consider the machine’s capacity and throughput to ensure it meets your recycling needs. Investing in a shredder with adjustable settings can allow for flexibility in processing different materials, enhancing overall productivity. Remember, a machine that’s easy to maintain and has a reliable warranty will provide peace of mind and long-term value.

In recent years, plastic shredders have become pivotal in enhancing the efficiency of recycling operations across various facilities. One noteworthy case study involves a large-scale recycling plant in Germany that implemented a high-performance plastic shredder to streamline its processing capabilities. Before the upgrade, the plant faced challenges with material separation and throughput. However, after integrating the advanced shredder, they reported a significant reduction in processing time and an increase in recycled material quality. This transformation not only boosted their operational efficiency but also helped them meet local recycling targets more effectively.

Another compelling example can be seen in a community recycling initiative in California. By employing small but robust plastic shredders, the initiative managed to significantly reduce waste sent to landfills. The shredders allowed the team to break down collected plastic items into manageable sizes, making it easier to sort and process them for recycling. This hands-on approach not only educated the community about recycling but also fostered a culture of sustainability. The project demonstrated that even smaller-scale implementations of plastic shredders can lead to meaningful improvements in recycling outcomes and heightened awareness around plastic waste.