In the growing field of sustainable practices, tire shredding stands out as an essential method for effective recycling. Experts like Dr. Emily Carter, a leading authority in tire recycling technologies, emphasizes, “Innovative tire shredding techniques can dramatically enhance material recovery.” Her insights highlight the urgent need for more efficient processes in this industry.

Tire shredding involves breaking down old tires into smaller pieces, allowing for better reuse. The challenge is to refine these techniques to improve efficiency and reduce waste. Many methods exist today, but not all techniques provide the same level of effectiveness. It’s crucial to analyze which processes yield the best results. For example, granulation and cryogenic shredding are gaining attention, but some practitioners question their environmental impact.

As the tire industry evolves, it's vital to adapt and innovate. The increase in tire waste calls for improved methods. Yet, tire shredding processes can sometimes fall short, requiring ongoing reflection and improvement. Understanding these nuances can lead us closer to a more sustainable future in tire recycling.

Tire shredding plays a pivotal role in the recycling industry. Many techniques have been developed to make this process more efficient. The focus is not just on breaking tires down but on doing it effectively. One common method is the use of mechanical shredders. These machines cut tires into smaller pieces, facilitating further processing.

Another technique involves cryogenic processing. This process uses liquid nitrogen to freeze tires. Once frozen, they become brittle and easy to shatter. This method minimizes contamination and produces cleaner rubber particles. However, it can be costly and requires specialized equipment.

Current techniques also face challenges. Not all tire types can be processed the same way. The diversity in tire construction makes standardization difficult. Recycling facilities often struggle to keep up with the demand for processed rubber. They need innovative solutions to address inefficiencies and waste. Exploring new methods will be essential for the industry's progress. Each technique holds potential but needs careful evaluation and adaptation.

Tire shredding has become an essential technique in recycling materials effectively. The process allows for the transformation of discarded tires into useful products. When tires are shredded, it becomes easier to separate rubber from steel and other materials. This separation is crucial for maximizing recovery.

Shredded tires can be used in various applications. They are often turned into asphalt for roads, playground surfaces, and even fuel. Recycling through shredding reduces landfill waste significantly. It also helps to conserve natural resources. However, the impact of tire shredding is sometimes underestimated. Many people are unaware of its potential benefits.

Tips for effective tire shredding include:

Tire shredding is a vital process in recycling. Various techniques have emerged, each with unique advantages. Mechanical shredding utilizes large machines to cut tires into specific sizes. This method is efficient but can lead to uneven particle sizes. Operators need to frequently adjust settings to ensure consistency, which can be a challenge.

Another approach is cryogenic shredding. This method involves cooling tires with liquid nitrogen. The extreme cold makes the rubber brittle. This allows for cleaner, finer particles. However, the cost of equipment and energy can be high. Not all facilities can justify this investment.

Water jet cutting is gaining attention too. It uses high-pressure water to slice through tires. This technique minimizes noise and vibration. Yet, it generates a significant amount of sludge that requires proper disposal. Facilities must be prepared to handle this waste effectively. Balancing efficiency and environmental responsibility in tire shredding remains an ongoing challenge.

Effective tire recycling techniques play a crucial role in reducing environmental impact. According to a report by the Environmental Protection Agency (EPA), around 300 million tires end up in landfills each year in the U.S. This represents a significant source of waste. When tires are not recycled, they can release harmful chemicals into the environment. Moreover, they can take more than a century to decompose.

Tire shredding is one effective approach to recycling. It transforms used tires into smaller pieces, making them easier to repurpose. A study indicated that recycled tires can be used in asphalt mixtures for roads, enhancing durability and performance. This process can reduce the need for new raw materials and decrease carbon emissions by up to 40%. However, the practices are still evolving. Some facilities struggle with the proper disposal of steel and fibers from tires.

Despite advancements, challenges remain in tire recycling. The most common recycling method is mechanical shredding, but it generates noise and waste. Finding ways to minimize these issues is essential. As technologies improve, ongoing assessment is necessary to maintain environmentally friendly practices. The goal should be to create a sustainable cycle that maximizes resources while mitigating harmful effects on our planet.

| Technique | Efficiency (%) | Environmental Impact | Cost ($/ton) |

|---|---|---|---|

| Cryogenic Shredding | 90 | Low Emissions | 200 |

| Mechanical Shredding | 80 | Moderate Emissions | 150 |

| Granulation | 85 | Low Waste | 180 |

| Shredding & Separating | 92 | Minimal Pollution | 220 |

| Hydraulic Shredding | 75 | Higher Emissions | 160 |

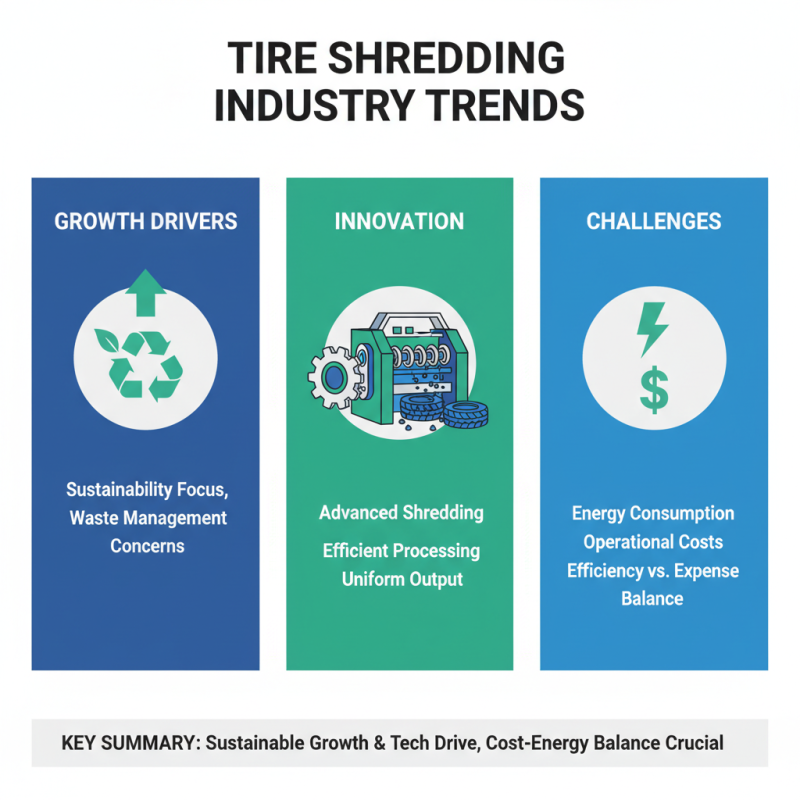

In recent years, the tire shredding industry has seen significant growth, driven by increased focus on sustainability. The rising concerns about waste management have led to innovative techniques in tire recycling. One notable trend is the use of advanced shredding machines. These machines can process tires more efficiently, producing smaller, uniform pieces. However, industry players face challenges in energy consumption and operational costs. The balance between efficiency and expenses is crucial.

Statistical insights indicate a steady increase in tire recycling rates globally. In some regions, the recycling rate has surpassed 50%. The market also sees a shift towards eco-friendly methods. More companies are adopting green practices. Yet, some still rely on outdated technologies. This discrepancy highlights the need for reflection in operational choices. Many operators have a long way to go in adopting best practices.

Consumer awareness is also growing. Many customers are now seeking products made from recycled tires. This shift in consumer behavior drives demand for recycled materials. The tire shredding industry must adapt to meet these new expectations. Understanding market dynamics and consumer preferences is essential for future growth. As the industry evolves, only those who embrace change will thrive.